Understanding “Cemento Para Parchar”: A Comprehensive Guide

October 9, 2024“Cemento Para Parchar” translates to “patching cement” in English, a crucial material for various construction and repair projects. Whether you’re a DIY enthusiast or a seasoned contractor, understanding the nuances of patching cement can be incredibly beneficial. This guide delves into the intricacies of this versatile material, exploring its types, applications, and best practices for achieving professional-grade results.

What is Patching Cement?

Patching cement is a pre-mixed blend of cement, sand, and other additives designed for repairing concrete surfaces. Its unique formulation allows for excellent adhesion, durability, and a seamless finish, making it ideal for fixing cracks, holes, and imperfections in concrete structures.

Types of Patching Cement

Choosing the right type of patching cement is vital for project success. Here are some common varieties:

- Hydraulic Cement: Known for its rapid setting time, hydraulic cement is ideal for urgent repairs and underwater applications.

- Epoxy Cement: Offering superior bonding strength and chemical resistance, epoxy cement is perfect for high-traffic areas and industrial settings.

- Latex-Modified Cement: This type provides enhanced flexibility and crack resistance, making it suitable for patching driveways, patios, and sidewalks.

Different Types of Patching Cement

Different Types of Patching Cement

Applications of Patching Cement

The versatility of patching cement extends to a wide array of applications:

- Repairing Cracks in Concrete: From hairline cracks to larger fissures, patching cement effectively restores the structural integrity of concrete surfaces.

- Filling Holes and Gaps: Whether caused by wear and tear or previous installations, patching cement seamlessly fills in holes and gaps, creating a smooth and even surface.

- Leveling Uneven Concrete: Patching cement can be used to level out minor unevenness in concrete floors, ensuring a stable and aesthetically pleasing finish.

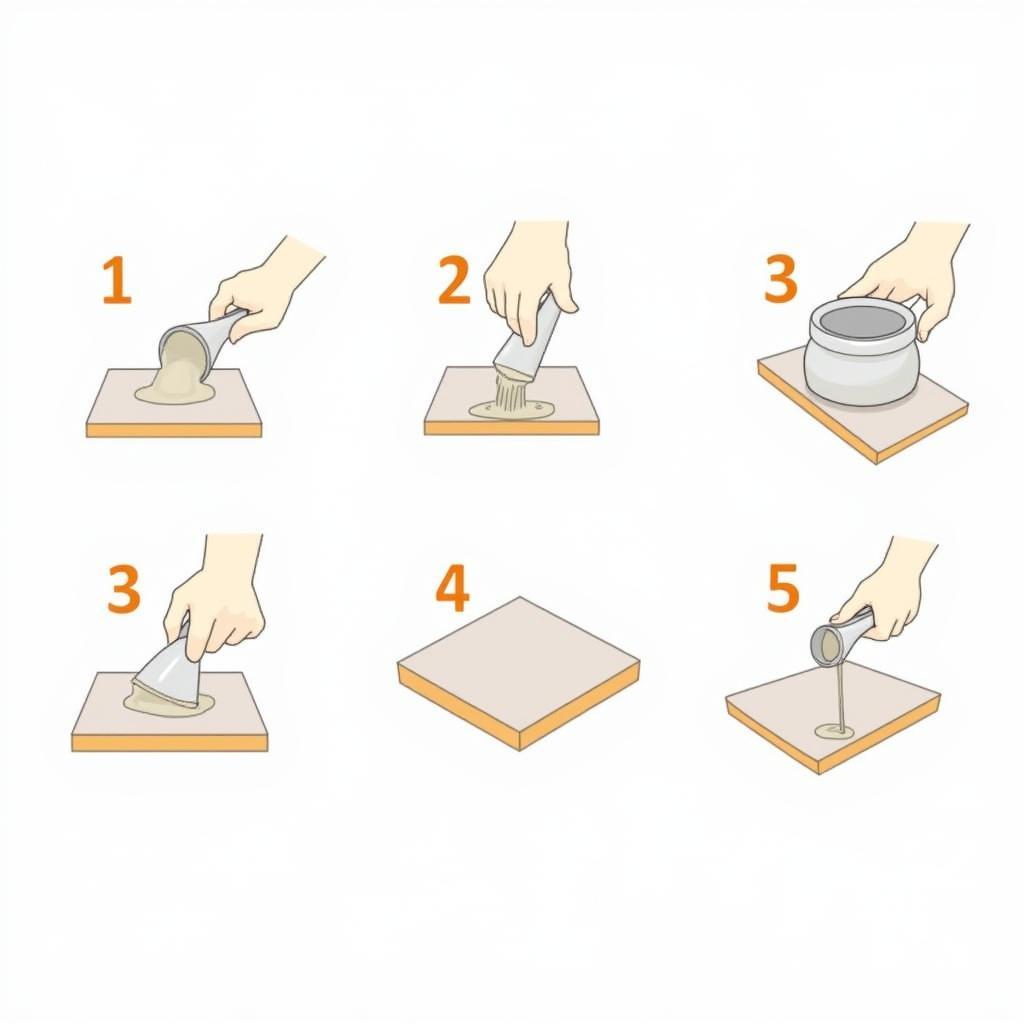

How to Use Patching Cement

Achieving optimal results with patching cement involves a systematic approach:

- Preparation is Key: Thoroughly clean the area to be patched, removing any loose debris, dirt, or contaminants.

- Mixing the Cement: Follow the manufacturer’s instructions carefully, adding the correct amount of water and mixing until a consistent, workable paste is achieved.

- Applying the Patch: Apply the patching cement to the repair area using a trowel or putty knife, pressing firmly to ensure proper adhesion.

- Finishing Touches: Smooth out the surface using a trowel or float, blending the patch seamlessly with the surrounding concrete.

- Curing Time: Allow the patching cement to cure completely according to the manufacturer’s recommendations before subjecting it to traffic or heavy loads.

Steps to Apply Patching Cement

Steps to Apply Patching Cement

Tips for Success

- Choose the Right Cement: Consider the specific requirements of your project, such as the size and location of the repair, when selecting the appropriate type of patching cement.

- Proper Surface Preparation: A clean and well-prepared surface is crucial for optimal adhesion and a long-lasting repair.

- Don’t Overwater: Adding too much water to the mix can weaken the cement and compromise its strength.

- Work Quickly: Patching cement tends to set relatively fast, so it’s essential to work efficiently once the mixing process is complete.

Conclusion

“Cemento para parchar,” or patching cement, is an indispensable material for maintaining and restoring concrete structures. By understanding its properties, applications, and best practices for use, you can confidently tackle a wide range of repair projects. From minor cracks to larger imperfections, patching cement provides a durable and aesthetically pleasing solution, ensuring the longevity and integrity of your concrete surfaces.

FAQs

1. How long does patching cement take to dry?

Drying time varies depending on the type of patching cement and environmental factors, but most products dry to the touch within 24 hours.

2. Can I use patching cement outdoors?

Yes, many patching cement products are specifically designed for outdoor use, offering resistance to weathering and UV exposure.

3. How do I prevent cracks from reappearing after patching?

Addressing the underlying cause of the cracks, such as settling or expansion, is essential to prevent them from reappearing.

4. Can I paint over patching cement?

Yes, once the patching cement has cured completely, it can be painted over to match the surrounding concrete surface.

5. Where can I buy patching cement?

Patching cement is readily available at most hardware stores, home improvement centers, and online retailers.

Need Assistance?

For expert advice and support on all your patching cement needs, don’t hesitate to reach out to our team. Contact us at:

Phone: +84 915 117 113

Email: [email protected]

Address: To 3 Kp Binh An, Phu Thuong, Viet Nam, Binh Phuoc 830000, Vietnam

We’re here to help you achieve professional-grade results with confidence!