Understanding the R8 Face Mill

November 6, 2024R8 Face Mills are essential tools in the machining industry, renowned for their ability to efficiently remove material from flat surfaces. Whether you’re a seasoned machinist or just starting out, understanding the intricacies of the r8 face mill can significantly improve your machining processes. This article will delve into the key features, benefits, and applications of r8 face mills, providing you with the knowledge you need to choose the right tool for your specific needs.

What is an R8 Face Mill?

An r8 face mill is a cutting tool used in milling machines to create flat surfaces. The “R8” refers to the specific taper of the shank, which is designed to fit into an R8 collet, a common tool holding system in many milling machines. This type of face mill is particularly popular in smaller machine shops and for hobbyists due to its versatility and ease of use. They are ideal for facing, surfacing, and profiling operations.

Advantages of Using an R8 Face Mill

R8 face mills offer several key advantages:

- Versatility: They can be used on a wide range of materials, from aluminum and steel to plastics and composites.

- Ease of Use: The R8 shank makes changing tools quick and simple.

- Cost-Effective: R8 face mills are often more affordable than other tooling options, making them a great choice for smaller shops and hobbyists.

- Availability: They are readily available from a variety of suppliers.

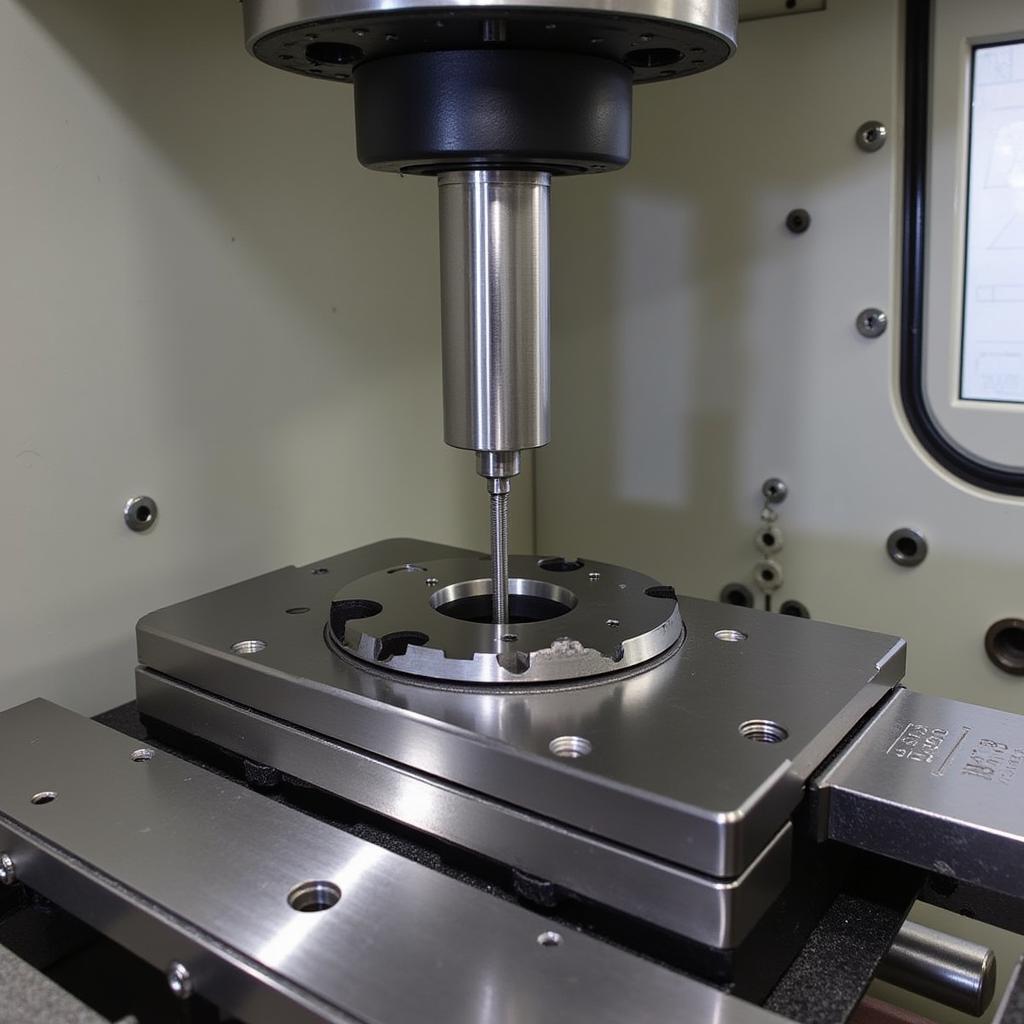

R8 Face Mill Machining a Steel Block

R8 Face Mill Machining a Steel Block

Choosing the Right R8 Face Mill

Selecting the appropriate r8 face mill depends on several factors, including the material being machined, the desired surface finish, and the power of your milling machine.

- Material: Different materials require different cutting insert geometries and coatings. For example, carbide inserts are typically used for harder materials like steel, while high-speed steel (HSS) inserts are suitable for softer materials like aluminum.

- Surface Finish: The number of inserts and their arrangement on the mill will impact the surface finish. More inserts generally result in a smoother finish.

- Machine Power: Larger face mills require more power to operate effectively. Ensure your milling machine has sufficient horsepower to handle the chosen mill.

Common Applications of R8 Face Mills

R8 face mills are used in a wide variety of machining applications:

- Facing: Creating a flat surface perpendicular to the tool axis.

- Surfacing: Machining a large flat area.

- Profiling: Creating contoured surfaces.

- Shoulder Milling: Machining a shoulder or step in a workpiece.

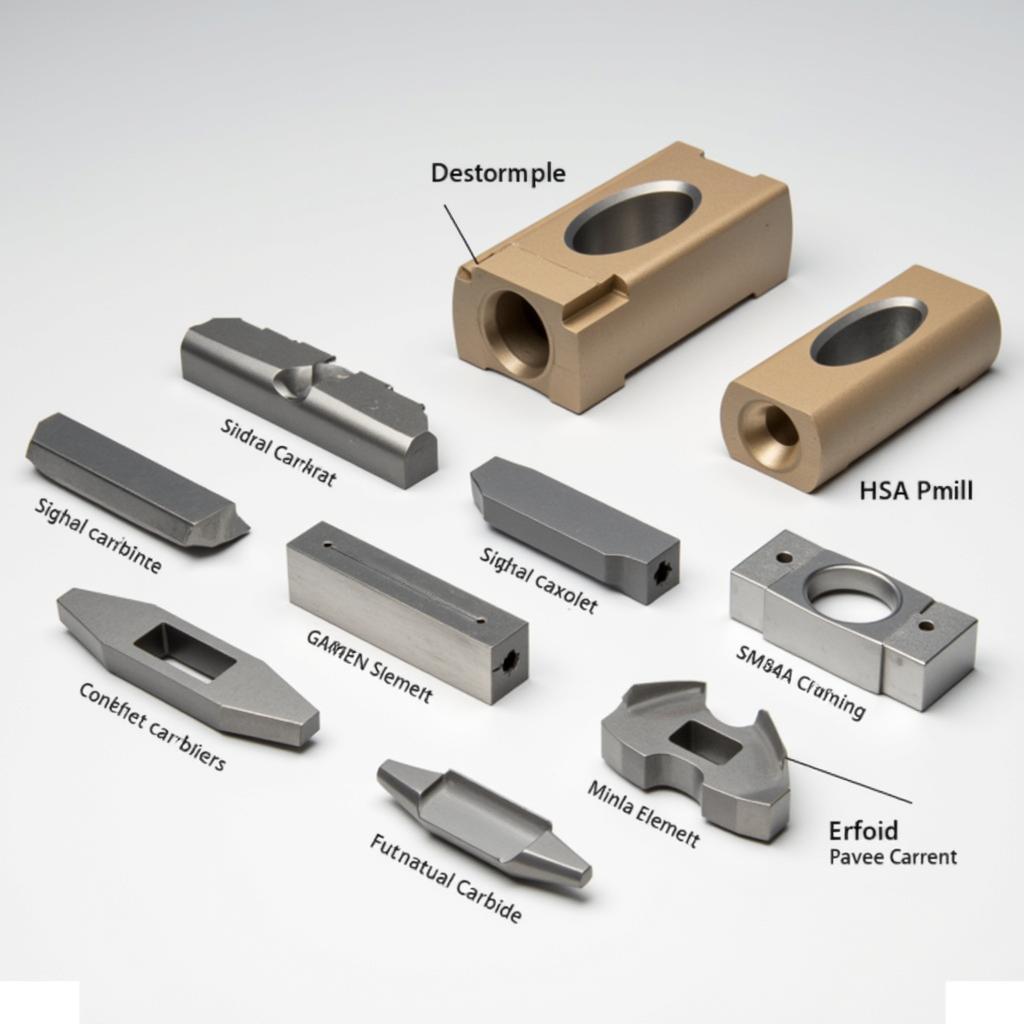

Different Inserts for R8 Face Mills

Different Inserts for R8 Face Mills

Maintaining Your R8 Face Mill

Proper maintenance is essential for extending the life of your r8 face mill and ensuring optimal performance.

- Cleaning: Regularly clean the mill to remove chips and debris.

- Insert Replacement: Replace worn or damaged inserts promptly.

- Storage: Store the mill in a clean, dry environment to prevent rust and corrosion.

Key Considerations for Optimal Performance

To achieve the best results with your r8 face mill, consider these additional tips:

- Proper Speed and Feed Rates: Using the correct speed and feed rates for the material being machined is crucial for achieving optimal performance and preventing tool breakage.

- Coolant: Using coolant can help to dissipate heat, extend tool life, and improve surface finish.

- Rigidity: Ensure the workpiece is securely clamped and the milling machine is rigid to minimize vibrations.

Proper Setup of R8 Face Mill in Milling Machine

Proper Setup of R8 Face Mill in Milling Machine

Conclusion

The r8 face mill is a versatile and cost-effective tool that can significantly improve your machining processes. By understanding its features, benefits, and applications, you can choose the right r8 face mill for your needs and achieve optimal performance. Remember to maintain your mill properly and follow best practices for speed, feed, and coolant to maximize its lifespan and efficiency.

FAQ

- What is the difference between an r8 face mill and other face mills?

- What materials can be machined with an r8 face mill?

- How do I choose the right inserts for my r8 face mill?

- What are the recommended speed and feed rates for different materials?

- How do I maintain my r8 face mill?

- What are some common problems encountered when using an r8 face mill?

- Where can I purchase r8 face mills and inserts?

For further assistance, please contact us: Phone: 0915117113, Email: [email protected] or visit our address: Group 3, Binh An Hamlet, Phu Thuong, Vietnam, Binh Phuoc 830000, Vietnam. We have a 24/7 customer service team.