How to Make Tracer Ammo

November 8, 2024Tracer ammo, with its distinctive glowing trail, has captivated shooters and military enthusiasts for decades. Whether you’re interested in the practical applications, the fascinating science behind it, or simply the visual spectacle, understanding how tracer ammo is made is a journey into the world of ballistics and pyrotechnics. This article delves into the intricate process of creating this unique ammunition.

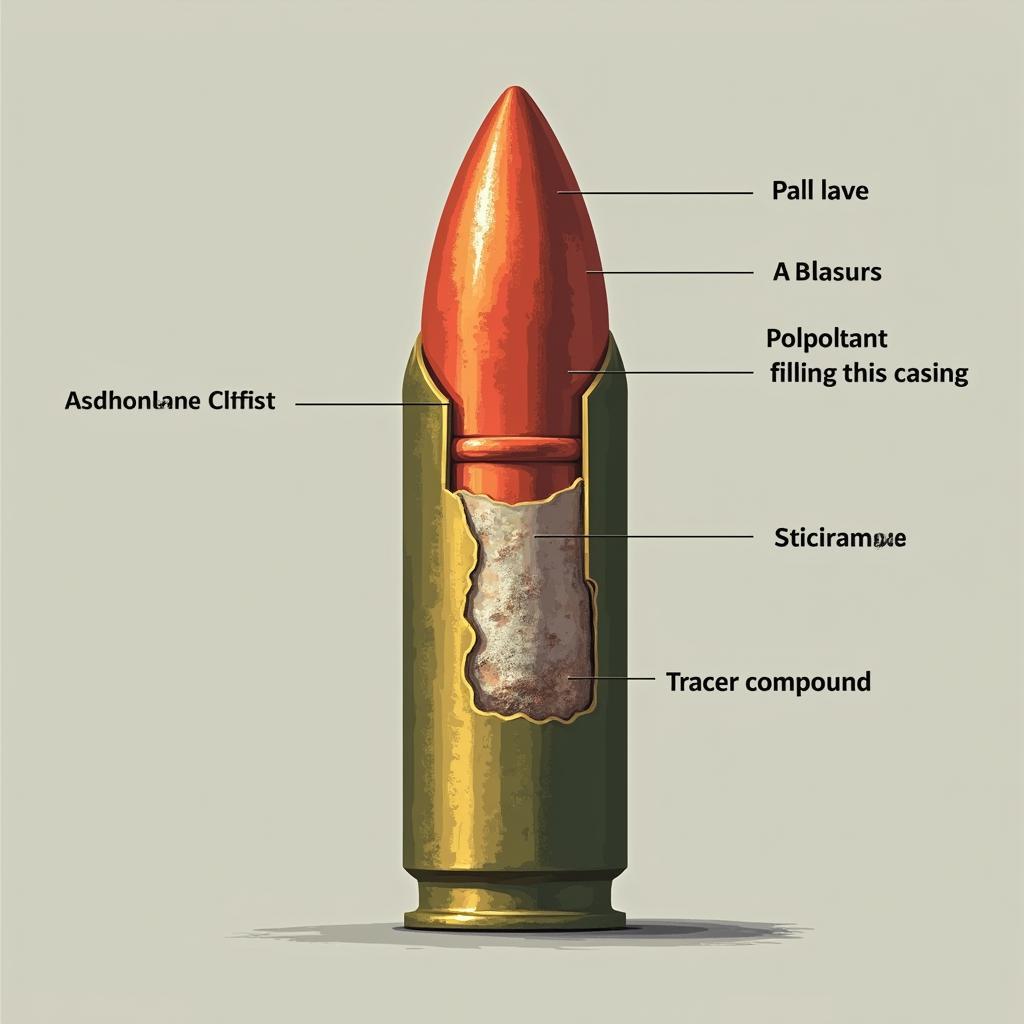

Understanding the Components of Tracer Ammo

Tracer rounds are more than just regular bullets with a glowing tip. They involve a carefully engineered combination of components working together to create that illuminating effect. The key elements include the bullet itself, the primer, the propellant, and, of course, the tracer compound. The bullet is typically similar to standard ammunition, designed for a specific caliber and purpose. The primer initiates the firing process, igniting the propellant, which in turn propels the bullet down the barrel. The tracer compound, located at the base of the bullet, is the star of the show, igniting upon firing and leaving the characteristic bright trail.

The tracer compound is a pyrotechnic composition that burns brightly when ignited. This composition varies depending on the desired burn time, color, and intensity of the trail. Common ingredients include magnesium, strontium, and other metallic salts that produce vibrant colors when burned. The careful selection and mixing of these chemicals determine the properties of the tracer round.

Tracer Ammo Components: Bullet, Primer, Propellant, and Tracer Compound

Tracer Ammo Components: Bullet, Primer, Propellant, and Tracer Compound

The Manufacturing Process of Tracer Ammo

The production of tracer ammo involves several precise steps to ensure safety and functionality. The process starts with the creation of the bullet itself, often through a process called swaging, where metal is shaped under high pressure. Then, the primer is inserted into the base of the casing. Next, the carefully measured propellant is added, followed by the crucial step of inserting the tracer compound. This requires specialized equipment to ensure the correct amount and placement of the pyrotechnic mixture. Finally, the bullet is seated into the casing, completing the assembly.

Quality control is paramount throughout the manufacturing process. Each step is carefully monitored to ensure consistency and adherence to strict specifications. This meticulous attention to detail guarantees the reliability and performance of the tracer ammo.

Tracer Ammo Manufacturing Process: Step-by-Step Assembly

Tracer Ammo Manufacturing Process: Step-by-Step Assembly

Different Types of Tracer Ammo

Not all tracer ammo is created equal. Variations exist in terms of burn time, color, and even the specific purpose they serve. Some tracer rounds are designed for short-range applications, with a shorter burn time to minimize the risk of giving away the shooter’s position. Others are intended for long-range use, with a longer burn time to aid in trajectory observation. Different colors are also employed, with red, green, and white being common choices, each potentially serving a different signaling or identification purpose.

For example, red tracers might be used for general target practice, while green tracers could be reserved for specific tactical scenarios. The specific characteristics of the tracer compound dictate these variations, allowing for customization based on the intended use.

Safety Precautions with Tracer Ammo

While visually captivating, tracer ammo requires careful handling and consideration due to its inherent fire hazard. The burning tracer compound can ignite dry grass, brush, or other flammable materials. Therefore, it’s crucial to use tracer ammo only in designated areas and to be mindful of the surrounding environment. Proper storage is also essential, keeping the ammunition away from heat sources and other potential hazards.

Conclusion

Creating tracer ammo is a complex process involving specialized knowledge and precision engineering. From the selection of the pyrotechnic compound to the meticulous assembly process, every step plays a critical role in the performance and safety of this unique ammunition. Understanding how tracer ammo is made offers a glimpse into the fascinating intersection of ballistics and chemistry. Remember to prioritize safety when handling tracer ammo and adhere to all relevant regulations and guidelines.

FAQ

- What is the purpose of tracer ammo? Primarily to visually track the trajectory of bullets, aiding in aiming and fire adjustment.

- Is tracer ammo legal? Legality varies by jurisdiction; check local laws and regulations.

- Can tracer ammo start fires? Yes, due to the burning tracer compound, it poses a fire hazard.

- How far can a tracer round be seen? Visibility depends on the specific tracer compound and environmental conditions.

- What are the different colors of tracer ammo used for? Different colors can be used for identification, signaling, or specific tactical purposes.

- How should tracer ammo be stored? Store in a cool, dry place away from flammable materials and heat sources.

- Where can I buy tracer ammo? Availability varies by location; check with licensed firearm dealers and follow local regulations.

Situations where frequently asked questions arise:

- When discussing firearm safety and responsible ammunition usage.

- During conversations about the practical applications of different ammunition types.

- In online forums or communities dedicated to firearms and shooting sports.

Related articles you may find helpful:

- Types of Ammunition and Their Uses

- Firearm Safety Guidelines

- Ballistics for Beginners

Contact us for assistance:

Phone Number: 0915117113

Email: [email protected]

Address: To 3 Kp Binh An, Phu Thuong, Vietnam, Binh Phuoc 830000, Vietnam. We have a 24/7 customer service team.