Ez Loader Hub Replacement: A Comprehensive Guide

November 30, 2024Ez Loader Hub Replacement can seem daunting, but with the right knowledge and tools, it can be a manageable DIY project. This guide provides a step-by-step approach to replacing your ez loader hubs, ensuring a smooth and safe trailering experience.

Understanding the Importance of Ez Loader Hub Replacement

Regular maintenance is crucial for the longevity and safety of your trailer. Ez loader hubs, like any mechanical component, are subject to wear and tear. Ignoring worn-out hubs can lead to bearing failure, wheel detachment, and potentially dangerous situations on the road. Knowing when and how to replace your ez loader hubs is essential for responsible trailer ownership.

Identifying the Right Ez Loader Hub for Your Trailer

Choosing the correct replacement hub is the first step in a successful ez loader hub replacement. Different trailers have different hub requirements based on weight capacity, axle type, and bolt pattern. Consulting your trailer’s owner’s manual or contacting a reputable trailer parts supplier will help you determine the correct hub specifications.

Matching Bolt Patterns and Weight Capacity

Ensuring the correct bolt pattern and weight capacity is critical. Mismatched bolt patterns will prevent the wheel from mounting properly, while insufficient weight capacity can lead to premature hub failure. Carefully measure your current hub’s bolt pattern and refer to your trailer’s specifications to choose the appropriate replacement.

Measuring the Ez Loader Hub Bolt Pattern

Measuring the Ez Loader Hub Bolt Pattern

Gathering the Necessary Tools and Materials

Before you begin the ez loader hub replacement process, gather all the necessary tools and materials. This will prevent interruptions and ensure a smooth workflow. Essential tools include a lug wrench, jack, jack stands, grease gun, and appropriate sockets. In terms of materials, you’ll need a new ez loader hub assembly, bearings, races, grease seal, and lug nuts.

Ensuring Quality Parts for Long-Lasting Performance

Using high-quality replacement parts is crucial for the longevity and reliability of your trailer’s hub assembly. Opting for reputable brands and avoiding cheap alternatives can save you money and headaches in the long run.

Tools and Materials for Ez Loader Hub Replacement

Tools and Materials for Ez Loader Hub Replacement

Step-by-Step Ez Loader Hub Replacement Procedure

- Safety First: Securely park your trailer on a level surface and chock the wheels opposite the side you’re working on.

- Remove the Wheel: Use the lug wrench to remove the lug nuts and carefully remove the wheel.

- Remove the Old Hub: Remove the dust cap, cotter pin, and castle nut. Slide the old hub and drum assembly off the axle.

- Install New Bearings and Races: Carefully press the new races into the hub using a bearing press or appropriate tools. Pack the new bearings with high-quality wheel bearing grease.

- Install the New Hub: Slide the new hub and drum assembly onto the axle. Install the new grease seal, washer, castle nut, and cotter pin.

- Reinstall the Wheel: Mount the wheel and tighten the lug nuts in a star pattern.

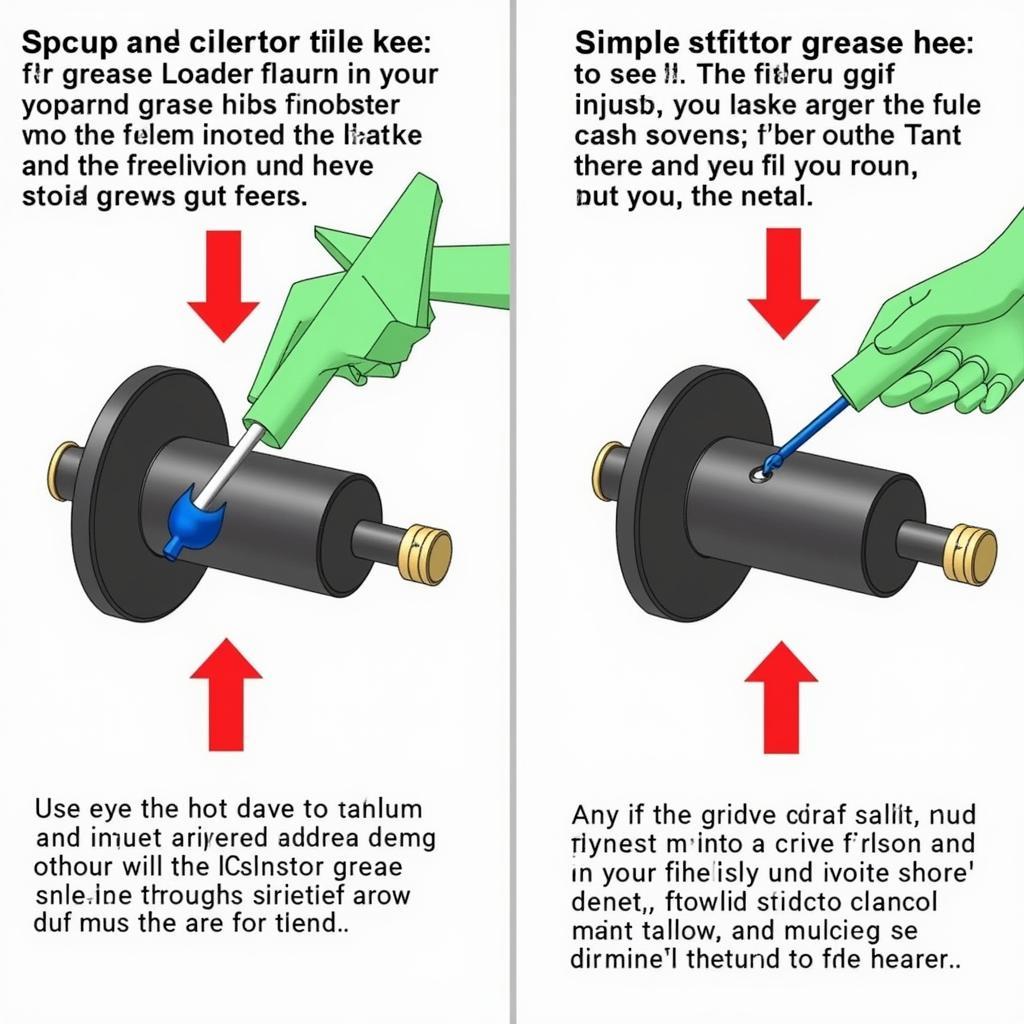

- Grease the Hub: Use a grease gun to inject grease into the hub through the grease fitting until new grease appears at the outer edge of the seal.

Torque Specifications and Proper Lubrication

Adhering to the manufacturer’s torque specifications for the lug nuts is essential for safety. Over-tightening or under-tightening can lead to wheel detachment or damage to the hub assembly. Proper lubrication of the bearings is also crucial for smooth operation and longevity.

Greasing the Ez Loader Hub

Greasing the Ez Loader Hub

Conclusion

Ez loader hub replacement is a vital maintenance task that ensures safe and reliable trailering. Following the steps outlined in this guide and using quality parts will contribute to a trouble-free experience on the road. Remember to consult your trailer’s manual for specific instructions and torque specifications. Regularly inspecting and maintaining your trailer’s hubs will prolong their lifespan and prevent costly repairs down the line. By taking proactive measures and understanding the process, you can enjoy peace of mind knowing your trailer is in top condition.

FAQs

- How often should I replace my ez loader hubs? It depends on usage and conditions. Inspect your hubs annually or more frequently if you trailer in harsh environments.

- Can I replace just the bearings, or do I need a whole new hub? If the hub itself is damaged, it’s best to replace the entire assembly.

- What type of grease should I use for my ez loader hubs? Use a high-quality marine-grade wheel bearing grease.

- What are the signs of a failing ez loader hub? Unusual noises, excessive heat, and play in the wheel are signs of a potential problem.

- How much does it cost to replace an ez loader hub? The cost varies depending on the hub type and labor costs.

- Where can I buy replacement ez loader hubs? Reputable trailer parts suppliers and online retailers carry ez loader hubs.

- Do I need special tools to replace an ez loader hub? While some specialized tools can be helpful, basic hand tools are usually sufficient.

Common Ez Loader Hub Replacement Scenarios

- Noisy Hubs: Grinding or humming noises usually indicate worn bearings.

- Overheating Hubs: Excessive heat can be a sign of insufficient lubrication or damaged bearings.

- Wobbling Wheel: A wobbling wheel can be caused by a loose or damaged hub.

Related Articles and Further Information

For more information on trailer maintenance and repair, you can visit our other helpful articles on [website link to other relevant articles].

When you need assistance, please contact us at Phone Number: 0915117113, Email: [email protected] Or visit us at: To 3 Kp Binh An, Phu Thuong, Vietnam, Binh Phuoc 830000, Vietnam. We have a 24/7 customer service team.