Understanding the Power and Versatility of a 12 Shot Mortar Rack

October 14, 2024The term “12 Shot Mortar Rack” often evokes images of intense battles and powerful artillery. While this association isn’t entirely inaccurate, it’s crucial to understand the full scope of what a 12 shot mortar rack represents, moving beyond simplistic views. This article dives deep into the intricacies of this equipment, exploring its historical context, mechanical functionalities, and diverse applications across various fields.

Military Use of 12 Shot Mortar Rack

Military Use of 12 Shot Mortar Rack

A Glimpse into the Past: Evolution of Mortar Systems

Before delving into the specifics of a 12 shot mortar rack, it’s essential to appreciate the evolutionary journey of mortar systems. Mortars, as a concept, have existed for centuries, with rudimentary versions used in ancient warfare. The need for indirect fire support – the ability to strike targets hidden behind obstacles – led to the development and refinement of mortars.

Over time, these weapons transitioned from simple tubes launching projectiles to sophisticated systems with improved accuracy, range, and rate of fire. The introduction of mortar racks marked a significant leap forward. These racks, capable of holding multiple mortar rounds, enabled faster reloading and increased firepower, drastically changing battlefield dynamics.

Design and Components of a Mortar Rack

Design and Components of a Mortar Rack

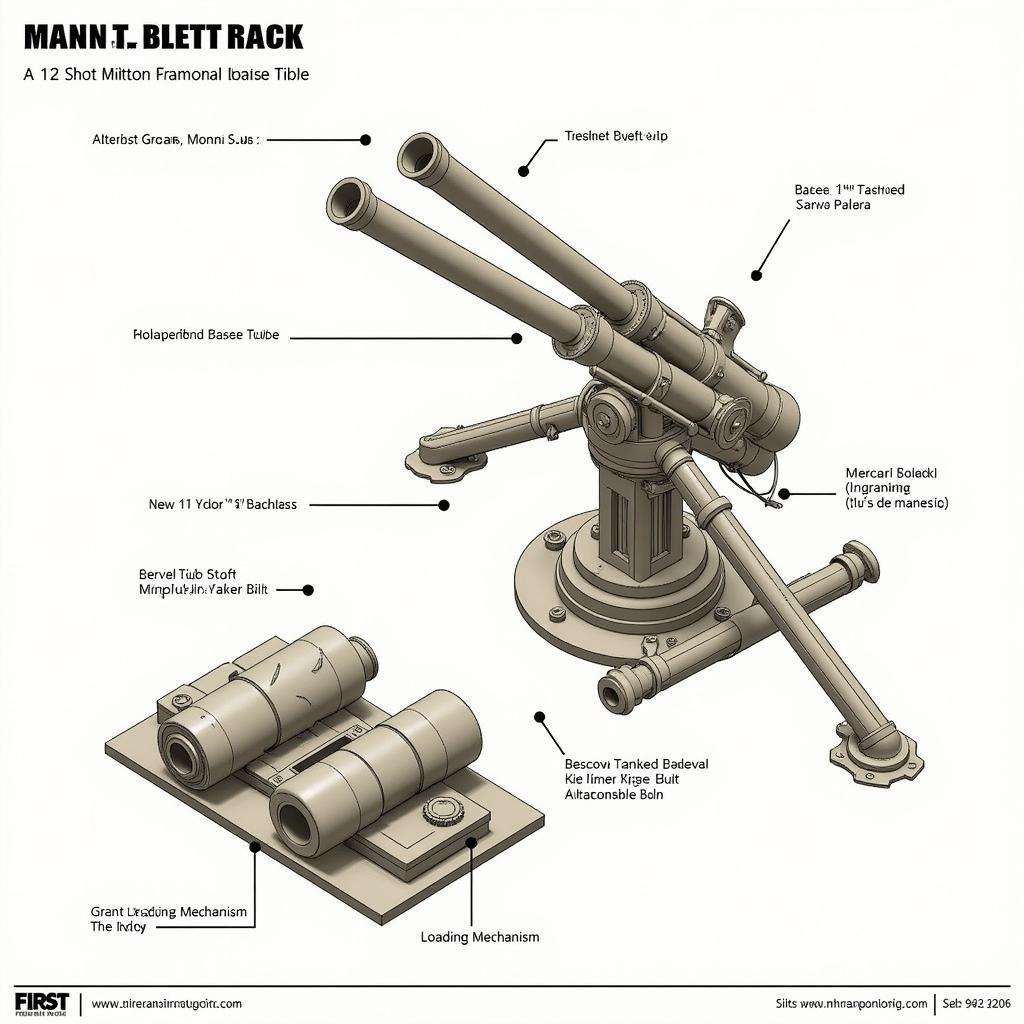

The Mechanics of a 12 Shot Mortar Rack: Precision Engineering at its Finest

A 12 shot mortar rack, as its name suggests, is designed to hold and fire twelve mortar rounds in quick succession. This capability is achieved through a combination of ingenious engineering and robust materials. The rack itself is typically constructed from high-grade steel or aluminum, ensuring durability and stability even under intense firing conditions.

The mortar tubes, the heart of the system, are precisely machined to provide consistent launch trajectories. These tubes are mounted on a sturdy base plate, often equipped with a traversing and elevating mechanism. This mechanism allows for fine-tuning the mortar’s aim, ensuring accurate targeting.

The loading mechanism, another critical component, facilitates the swift and safe loading of mortar rounds. It often involves a system of trays or clips that hold the rounds securely until they are ready to be fired. The entire assembly is designed for efficiency and speed, enabling operators to deliver a concentrated barrage of mortar fire with minimal downtime.

Beyond the Battlefield: Applications of 12 Shot Mortar Racks

While often associated with military operations, the applications of 12 shot mortar racks extend far beyond the battlefield. Their ability to launch projectiles with precision and power has made them valuable assets in various fields.

Avalanche Control:

In mountainous regions prone to avalanches, 12 shot mortar racks play a crucial role in mitigating risks. These racks are strategically positioned on slopes and used to trigger controlled avalanches. By releasing built-up snowpack in a controlled manner, the risk of large, destructive avalanches threatening populated areas is significantly reduced.

Fireworks Displays:

The captivating beauty of fireworks displays often relies on the precision and power of 12 shot mortar racks. These racks provide a safe and controlled platform for launching fireworks shells high into the sky, creating stunning aerial displays. Their ability to fire multiple shells in rapid succession allows for choreographed shows that captivate audiences worldwide.

Choosing the Right 12 Shot Mortar Rack: Factors to Consider

Selecting the appropriate 12 shot mortar rack depends on the specific application and a range of critical factors.

Mortar Caliber:

The caliber of the mortar rounds the rack is designed to handle is a primary consideration. Different calibers offer varying ranges and explosive payloads, impacting the system’s overall effectiveness for different purposes.

Portability:

The ease with which the rack can be transported and deployed is crucial, especially in scenarios requiring mobility. Factors like weight, size, and the presence of wheels or carrying handles significantly influence portability.

Durability:

The rack’s ability to withstand harsh environmental conditions and repeated use is essential for long-term reliability. Opting for racks constructed from high-quality materials and incorporating robust designs ensures longevity and consistent performance.

Conclusion: A Testament to Engineering Prowess

The 12 shot mortar rack, with its blend of power and precision, stands as a testament to human ingenuity in engineering. Its ability to deliver a concentrated barrage of firepower has shaped battlefields and found applications in diverse fields, from avalanche control to dazzling fireworks displays. Understanding its mechanics and diverse uses provides a deeper appreciation for this versatile and impactful piece of equipment.

Frequently Asked Questions

What is the effective range of a typical 12 shot mortar rack?

The effective range can vary significantly depending on the mortar caliber and the type of rounds used. However, many models have a maximum range of several kilometers.

Can a 12 shot mortar rack be operated remotely?

While traditional designs require manual operation, advancements in technology have led to remotely operated mortar systems, enhancing safety and tactical flexibility.

What safety precautions are essential when operating a 12 shot mortar rack?

Operating a 12 shot mortar rack demands strict adherence to safety protocols, including proper training, secure handling of explosives, and maintaining a safe distance during firing.

Need assistance or more information? Contact us at Phone Number: 0915117113, Email: [email protected] or visit us at: Tổ 3 Kp Bình An, Phú Thương, Việt Nam, Bình Phước 830000, Việt Nam. We have a dedicated customer support team available 24/7 to assist you.