Understanding 220 Volt Float Switches: A Comprehensive Guide

October 9, 2024A 220-volt float switch is a crucial component in liquid level control systems. It acts as an automatic switch, turning pumps on or off depending on the level of the liquid. This guide will delve into the intricacies of 220-volt float switches, covering their functionality, applications, installation, and more.

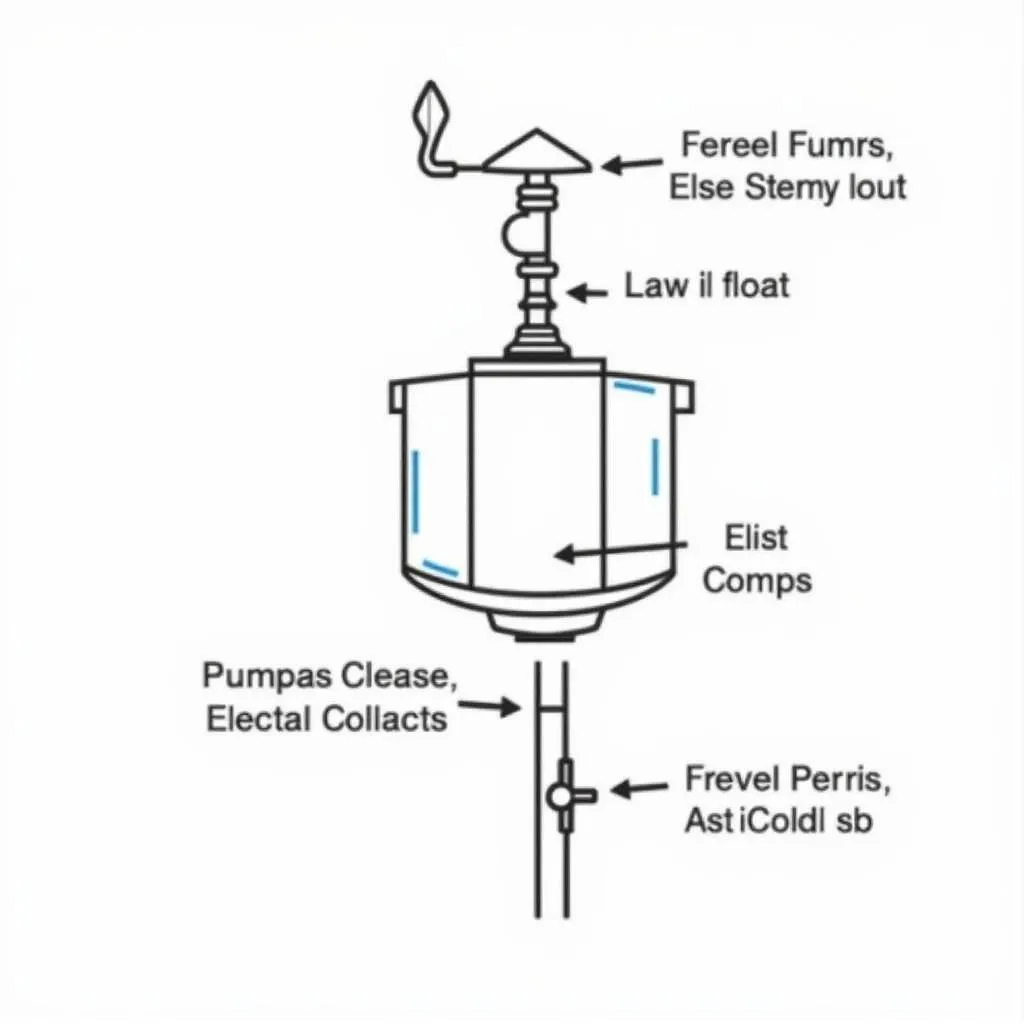

220V Float Switch Diagram

220V Float Switch Diagram

How Does a 220 Volt Float Switch Work?

A 220-volt float switch operates on a simple yet effective principle of buoyancy. Here’s a breakdown:

- The Float: A hollow, buoyant object, typically made of plastic or stainless steel, houses an internal switch mechanism.

- The Stem: Attached to the float, the stem provides a pivot point, allowing the float to move freely up and down with the liquid level.

- Electrical Contacts: Located within the switch housing, these contacts connect or disconnect the electrical circuit based on the float’s position.

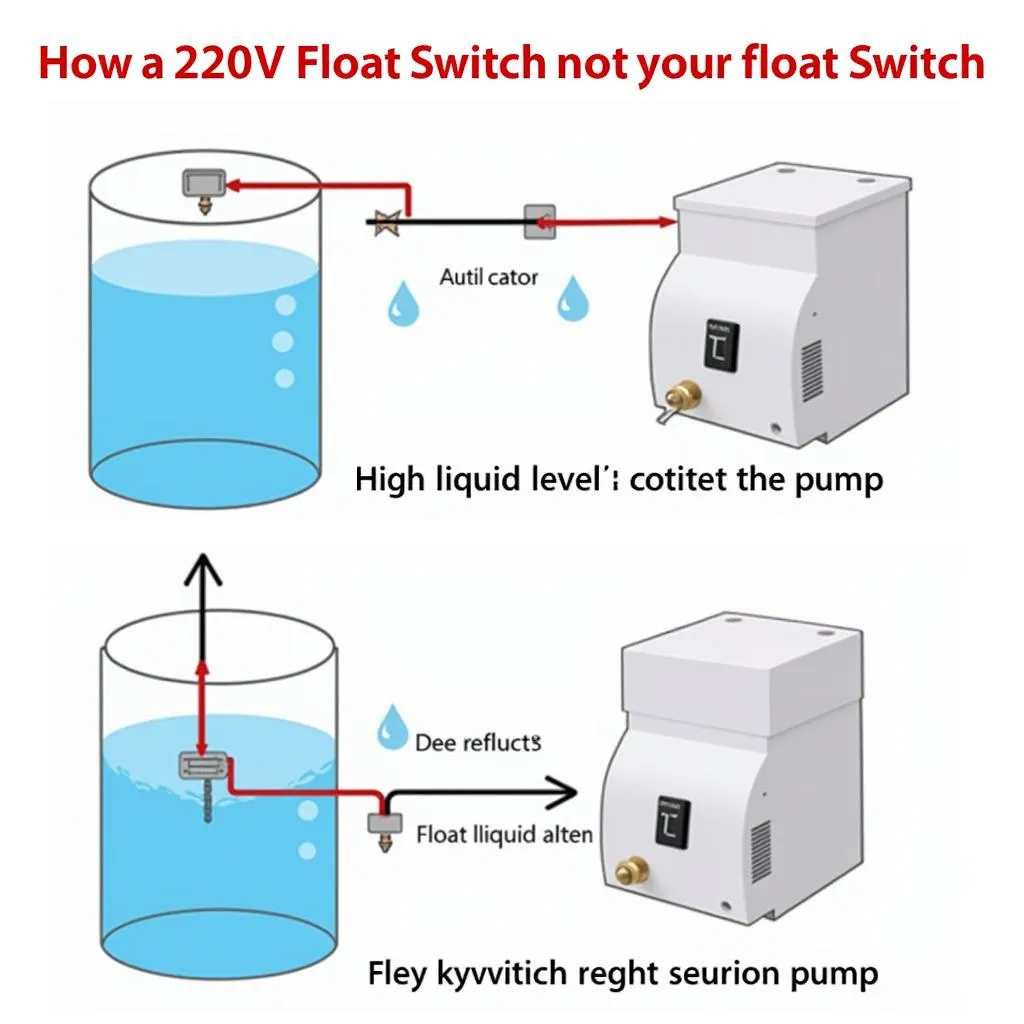

- Liquid Level Change: As the liquid level rises, it lifts the float, causing the stem to tilt and activate the internal switch. This closes the electrical circuit, turning the pump on. Conversely, when the liquid level drops, the float descends, opening the circuit and deactivating the pump.

Float Switch Operation in a Water Tank

Float Switch Operation in a Water Tank

Applications of 220 Volt Float Switches

The versatility of 220-volt float switches makes them suitable for a wide array of applications across residential, commercial, and industrial settings:

- Sump Pump Control: Preventing basement flooding by automatically activating sump pumps when water levels exceed a set point.

- Water Tower Level Management: Maintaining desired water levels in towers by controlling pumps that fill and empty them.

- Industrial Tank Monitoring: Regulating liquid levels in tanks used for storage, processing, or waste management.

- Pool and Spa Automation: Controlling water features, maintaining water levels, and managing filtration systems.

- Agriculture and Irrigation: Automating irrigation systems by activating pumps to water crops based on soil moisture or reservoir levels.

Types of 220 Volt Float Switches

220-volt float switches are available in various configurations to suit different applications:

- Single-Pole Float Switch: The most basic type, featuring one set of contacts that either open or close a single electrical circuit.

- Double-Pole Float Switch: Offering greater control, it has two sets of contacts, allowing it to control two separate circuits simultaneously.

- Normally Open (NO) Float Switch: In its default state, the circuit is open. When the float rises, the circuit closes, activating the pump.

- Normally Closed (NC) Float Switch: Opposite to NO, the circuit is closed by default. As the float rises, the circuit opens, deactivating the pump.

Choosing the Right 220 Volt Float Switch

Selecting the appropriate 220-volt float switch depends on several factors:

- Voltage and Current Rating: Ensure the switch can handle the voltage and current requirements of the pump and power supply.

- Material Compatibility: Choose a float and switch material that can withstand the specific liquid and its temperature.

- Cable Length and Type: Opt for a cable length suitable for the installation and a cable type resistant to the environment.

- Switching Capacity: Select a switch with a contact rating that can handle the pump’s power consumption.

Installation and Maintenance

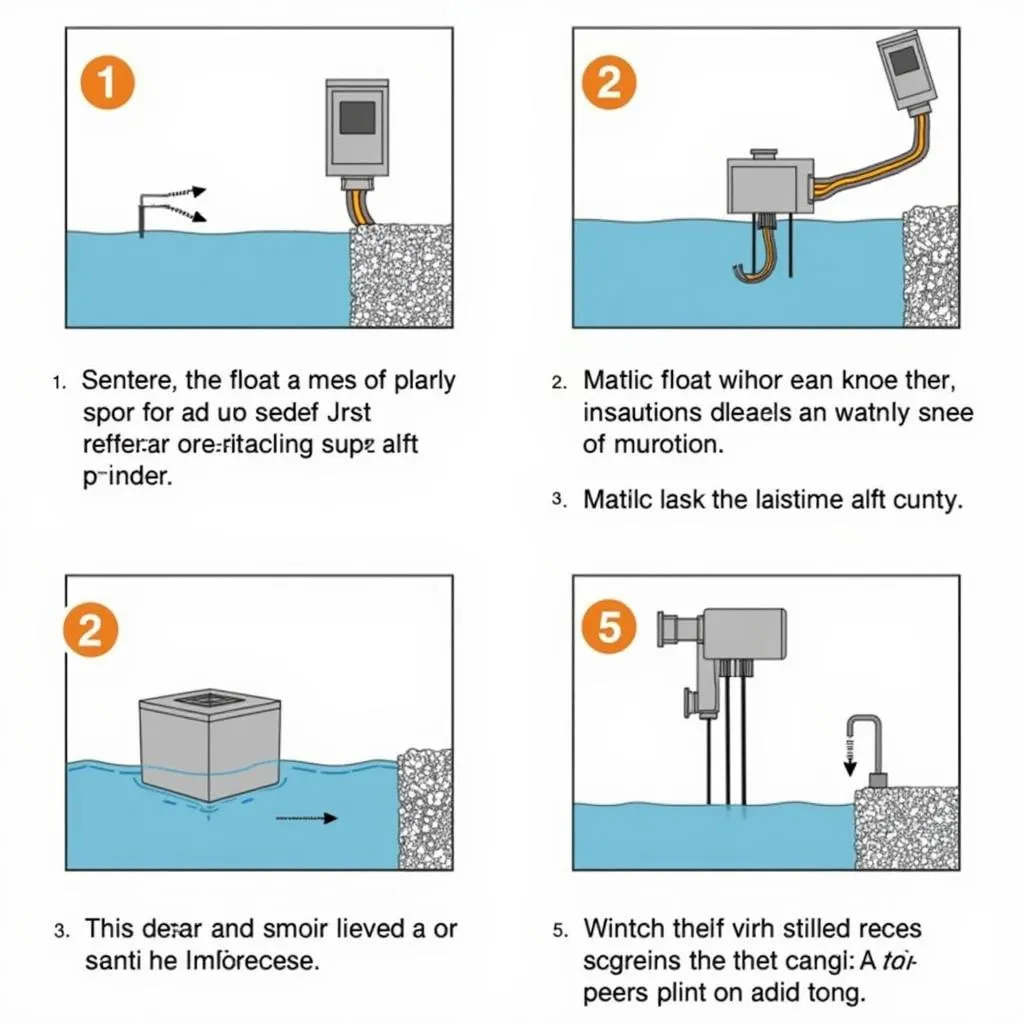

Proper installation and regular maintenance are crucial for optimal float switch performance:

- Installation: Follow the manufacturer’s instructions carefully. Mount the switch securely and ensure proper wiring connections.

- Maintenance: Regularly inspect the float for damage or debris buildup. Clean the switch as needed to prevent malfunctions.

Installing a 220V Float Switch in a Sump Pit

Installing a 220V Float Switch in a Sump Pit

Conclusion

220-volt float switches are essential components in fluid management, providing reliable and automated control over liquid levels. By understanding their functionality, applications, and selection criteria, you can effectively utilize these devices to simplify your liquid handling needs. For expert assistance or to explore a range of 220-volt float switch options, contact us at Phone Number: 0915117113, Email: [email protected], or visit our address: To 3 Kp Binh An, Phu Thuong, Viet Nam, Binh Phuoc 830000, Viet Nam. Our dedicated customer support team is available 24/7 to address your queries.