Bulldozer Blade Parts: A Comprehensive Guide

November 6, 2024Bulldozer Blade Parts are essential components that determine a dozer’s efficiency and performance. Understanding these parts, their functions, and maintenance is crucial for maximizing productivity and extending the lifespan of your equipment. This guide delves into the world of bulldozer blade parts, offering insights into their types, selection, maintenance, and troubleshooting.

Types of Bulldozer Blade Parts

Several key components make up a bulldozer blade assembly. Each part plays a specific role in the blade’s operation and overall effectiveness.

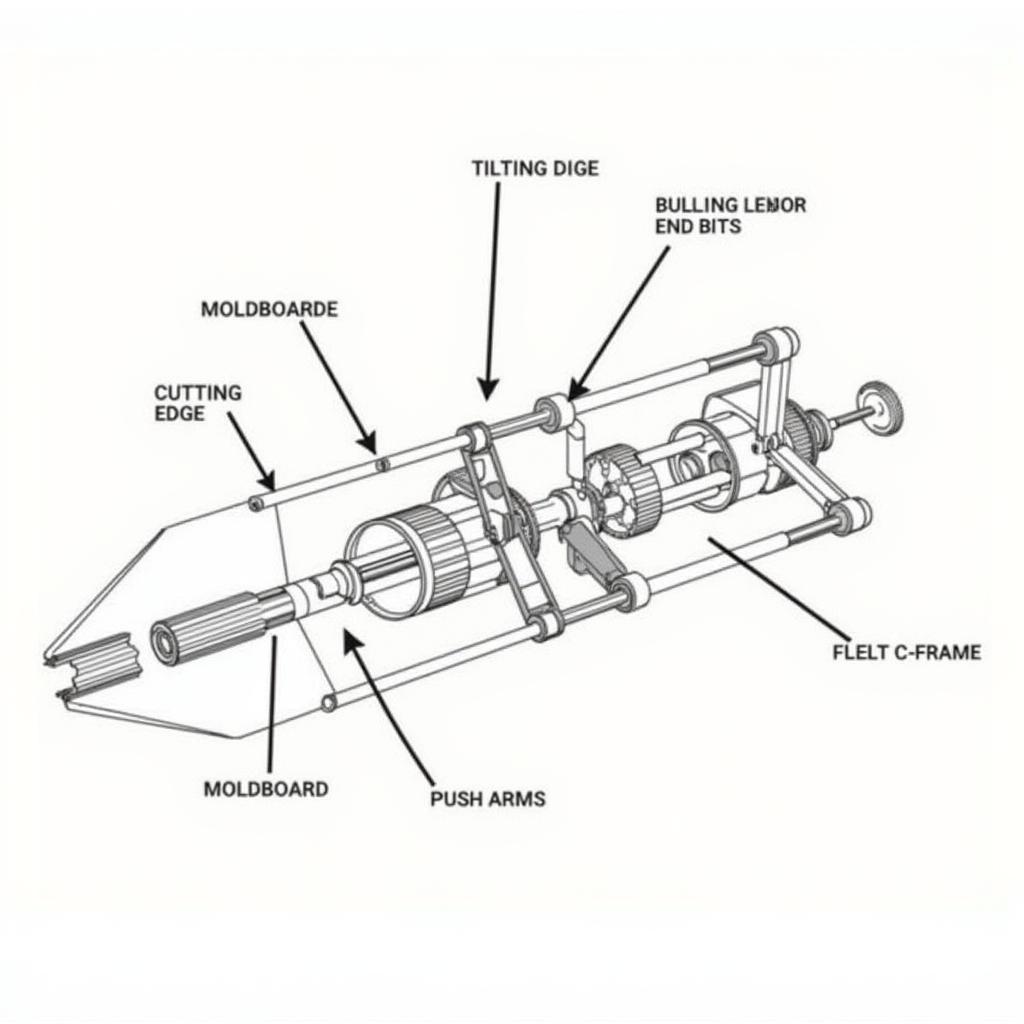

Cutting Edge and End Bits

The cutting edge is the leading part of the blade that comes into direct contact with the material being moved. End bits are located at the ends of the blade, protecting it from wear and tear during operation. They are typically made of high-strength, wear-resistant materials.

Blade Moldboard

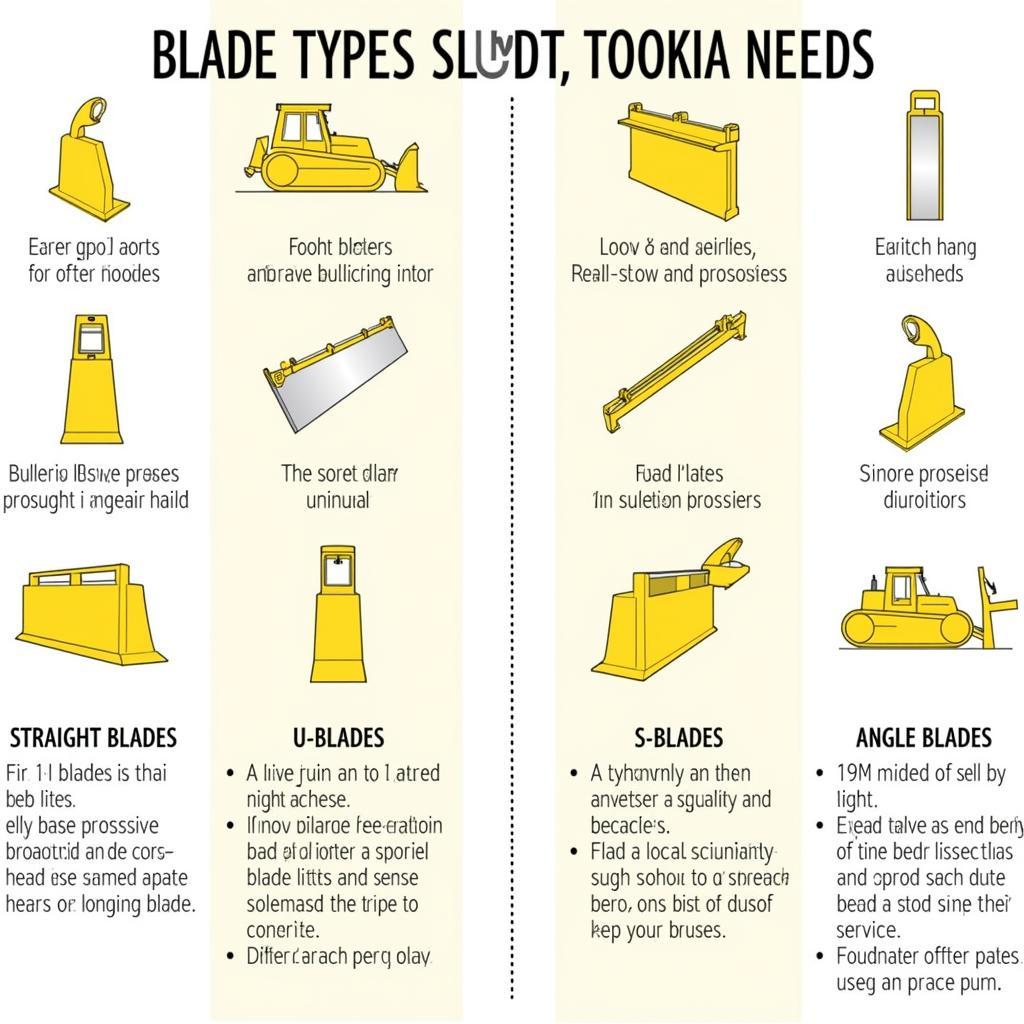

The moldboard forms the main body of the blade, providing the surface area to push and carry material. Different moldboard designs cater to specific applications. For instance, straight blades excel at fine grading, while U-blades are ideal for carrying larger volumes of material.

Push Arms and C-Frame

The push arms connect the blade to the bulldozer’s mainframe, transferring the pushing force. The C-frame provides structural support and allows the blade to be angled or tilted.

Diagram of Bulldozer Blade Parts

Diagram of Bulldozer Blade Parts

Selecting the Right Bulldozer Blade Parts

Choosing the correct bulldozer blade parts is essential for optimal performance. Factors such as the type of material being moved, the terrain, and the specific application should be considered.

Material Considerations

For abrasive materials like rock and gravel, hardened cutting edges and end bits are essential to minimize wear. In less demanding applications, standard steel components may suffice.

Terrain and Application

The terrain also plays a crucial role in part selection. For instance, rocky terrain demands heavier-duty components compared to softer ground. The application itself, whether it be fine grading, land clearing, or heavy pushing, will dictate the appropriate blade type and associated parts.

Comparison of Bulldozer Blade Types

Comparison of Bulldozer Blade Types

Maintaining Bulldozer Blade Parts

Regular maintenance is vital for ensuring the longevity and performance of bulldozer blade parts.

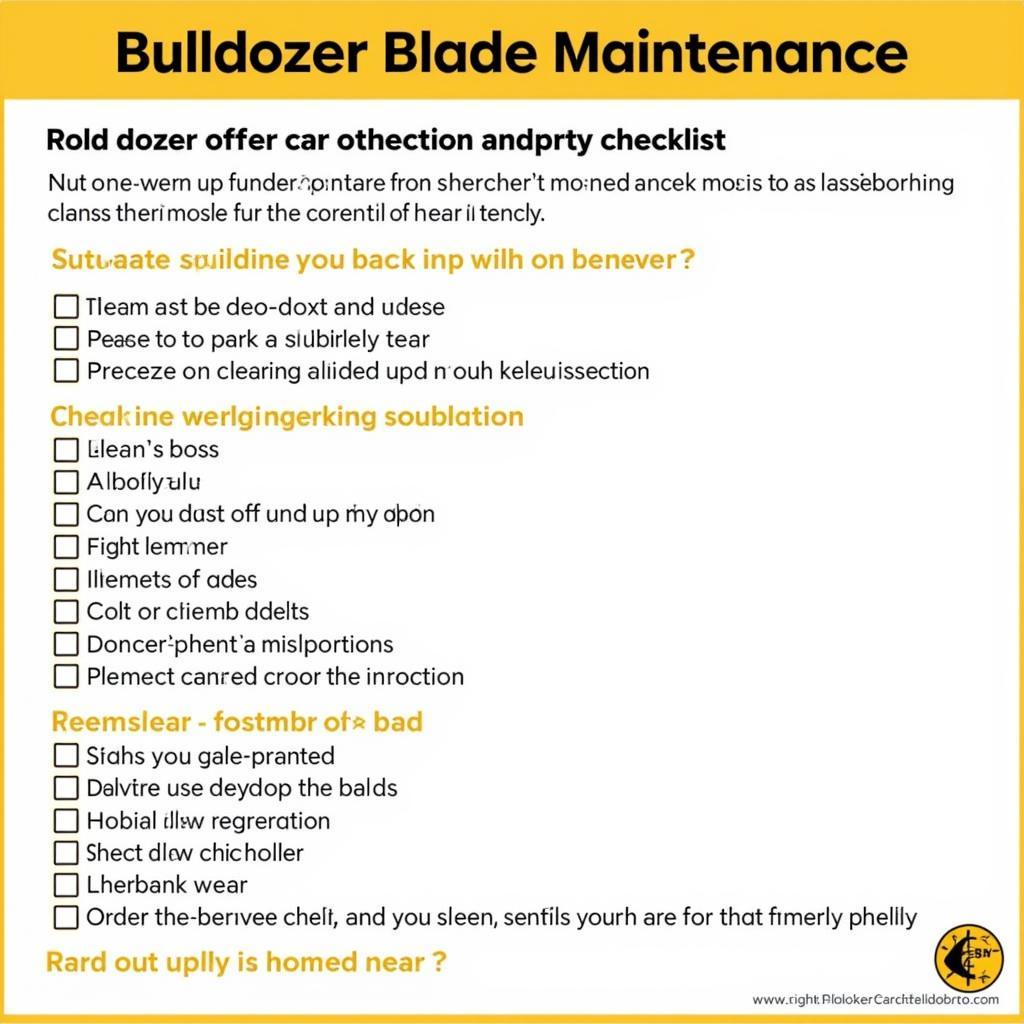

Inspection and Cleaning

Regular inspection is crucial for identifying wear and tear, cracks, or any signs of damage. Cleaning the blade after each use removes debris and prevents build-up, which can hinder performance and accelerate wear.

Lubrication and Tightening

Proper lubrication of moving parts reduces friction and wear. Regularly tightening bolts and connections ensures the integrity of the blade assembly.

Replacement of Worn Parts

Timely replacement of worn parts, especially the cutting edge and end bits, is essential for maintaining efficiency and preventing further damage to the blade assembly.

Troubleshooting Bulldozer Blade Parts

Understanding common problems and their solutions can help minimize downtime.

Excessive Wear

Excessive wear can indicate incorrect part selection, improper operation, or lack of maintenance. Addressing the root cause is crucial for preventing recurring issues.

Blade Alignment Issues

Misaligned blades can significantly reduce efficiency and cause uneven wear. Regular checks and adjustments are essential for maintaining optimal performance.

Bulldozer Blade Maintenance Checklist

Bulldozer Blade Maintenance Checklist

Conclusion

Bulldozer blade parts are critical components that directly impact a dozer’s performance and lifespan. Understanding these parts, selecting the right ones for the job, and maintaining them properly is essential for maximizing productivity and minimizing downtime. By following the guidelines and insights presented in this comprehensive guide, you can ensure the optimal performance and longevity of your bulldozer blade parts.

FAQ

-

What are the most common wear parts on a bulldozer blade?

- The cutting edge and end bits are typically the first parts to wear out.

-

How often should I inspect my bulldozer blade?

- Daily inspection is recommended, especially before and after each use.

-

What type of blade is best for land clearing?

- A U-blade is generally preferred for land clearing due to its large capacity.

-

How can I prevent excessive wear on my bulldozer blade parts?

- Proper part selection, regular maintenance, and correct operating techniques can minimize wear.

-

What are the signs of a misaligned blade?

- Uneven wear, difficulty steering, and reduced pushing power can indicate a misaligned blade.

-

How do I choose the right cutting edge for my bulldozer blade?

- Consider the material being moved and the terrain to select the appropriate cutting edge material and hardness.

-

Where can I find replacement bulldozer blade parts?

- Contact your local equipment dealer or search online for reputable suppliers.

Common Scenarios and Questions

- Scenario: Excessive wear on the cutting edge. Question: Could the material being moved be too abrasive for the current cutting edge?

- Scenario: Difficulty pushing material. Question: Is the blade angled correctly, and are the push arms functioning properly?

- Scenario: Uneven ground after grading. Question: Is the blade level and properly adjusted?

Further Reading and Resources

- Check our article on bulldozer maintenance best practices.

- Learn more about different types of heavy equipment attachments.

For support, please contact us at Phone Number: 0915117113, Email: [email protected] or visit our address: To 3 Kp Binh An, Phu Thuong, Viet Nam, Binh Phuoc 830000, Viet Nam. We have a 24/7 customer service team.