Fuel System Ol Drive: A Deep Dive

November 2, 2024Fuel System Ol Drive is a crucial aspect of internal combustion engines, particularly in older vehicles. This system manages the air-fuel mixture delivered to the engine cylinders, impacting performance, fuel efficiency, and emissions. Understanding its intricacies can be invaluable for classic car enthusiasts, mechanics, or anyone curious about the heart of their vintage vehicle.

Understanding how a fuel system ol drive works can greatly enhance your appreciation for older vehicles. Let’s explore this fascinating system in detail. One of the core components is the carburetor, responsible for mixing air and fuel in the correct proportions. This mixture is then drawn into the engine cylinders, where it is ignited to produce power. The “ol” in “fuel system ol drive” typically refers to “open loop,” indicating a system that doesn’t use feedback from sensors like oxygen sensors to adjust the air-fuel mixture. This is in contrast to newer “closed loop” systems that constantly monitor and adjust the mixture for optimal performance and emissions. Early fuel system ol drives relied heavily on mechanical components, offering a simple yet robust design.

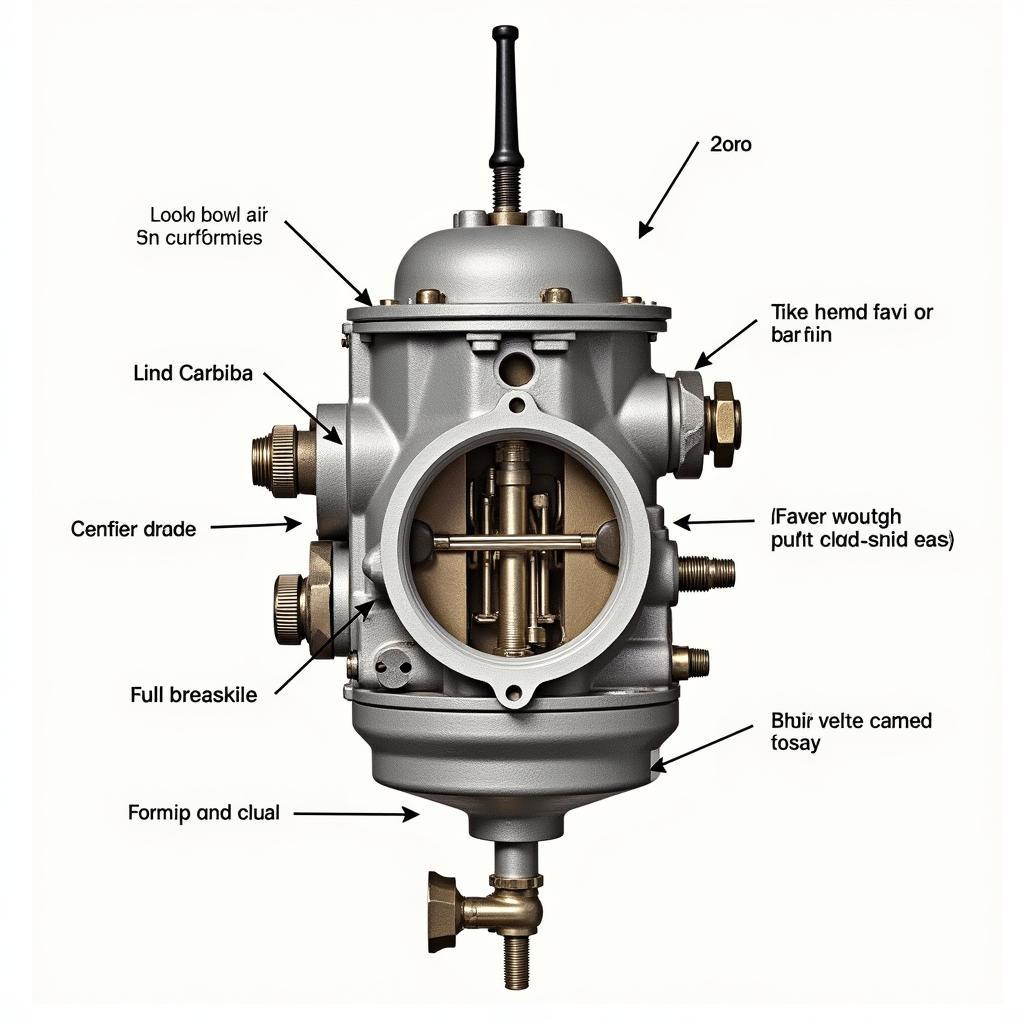

The Core Components of a Fuel System Ol Drive

A typical fuel system ol drive comprises several key components working in harmony. The fuel pump draws fuel from the tank and delivers it to the carburetor. The 4 folder may contain more information on these components. The carburetor then meters the fuel and mixes it with air drawn in through the intake manifold. This mixture is then distributed to the cylinders via the intake valves. This relatively simple system, compared to modern electronic fuel injection, offers a certain level of reliability and ease of maintenance.

The mechanical fuel pump is a critical element, driven by the engine’s camshaft to provide a continuous supply of fuel. The carburetor, often considered the heart of the system, uses a series of jets and valves to control the air-fuel ratio. This precise balance is essential for efficient combustion and smooth engine operation. Adjusting the carburetor can significantly impact performance, and understanding these adjustments is key for maximizing efficiency and responsiveness.

Carburetor in a Fuel System Ol Drive

Carburetor in a Fuel System Ol Drive

Troubleshooting Common Issues in a Fuel System Ol Drive

Common problems with fuel system ol drives include clogged fuel filters, faulty fuel pumps, and carburetor issues like a stuck float or clogged jets. These issues can lead to poor performance, hard starting, or even stalling. Regular maintenance, such as replacing fuel filters and cleaning the carburetor, can prevent many of these problems.

A thorough understanding of the system allows for quicker diagnosis and repair. For example, a sputtering engine might indicate a clogged fuel filter or a faulty fuel pump, while a rich or lean running condition often points to carburetor problems. Having basic tools and knowledge can save you time and money in the long run. Remember, regular maintenance is crucial for keeping your fuel system ol drive in top condition.

Advantages and Disadvantages of Fuel System Ol Drive

While simpler than modern fuel injection systems, fuel system ol drives have their pros and cons. They are generally less expensive to repair and easier to work on for the home mechanic. However, they are less fuel-efficient and produce more emissions than modern systems. They are also more susceptible to performance issues in extreme temperatures or altitudes.

Understanding the limitations of a fuel system ol drive is important. While they are generally reliable, they do require regular maintenance and adjustments to perform optimally. For instance, changes in altitude or temperature can affect the air-fuel mixture, necessitating adjustments to the carburetor. Check out our arena rank system.

Why Understanding Your Fuel System Matters

A well-maintained fuel system ol drive is crucial for the longevity and performance of your classic vehicle. By understanding how it works, you can diagnose problems more effectively and keep your vehicle running smoothly. This knowledge can also help you appreciate the engineering behind these vintage systems. The sports folder might have relevant info.

John Smith, a renowned classic car mechanic, emphasizes, “Understanding the nuances of a fuel system ol drive is like unlocking a secret code to your classic car’s performance. It empowers you to keep your vehicle running at its best.”

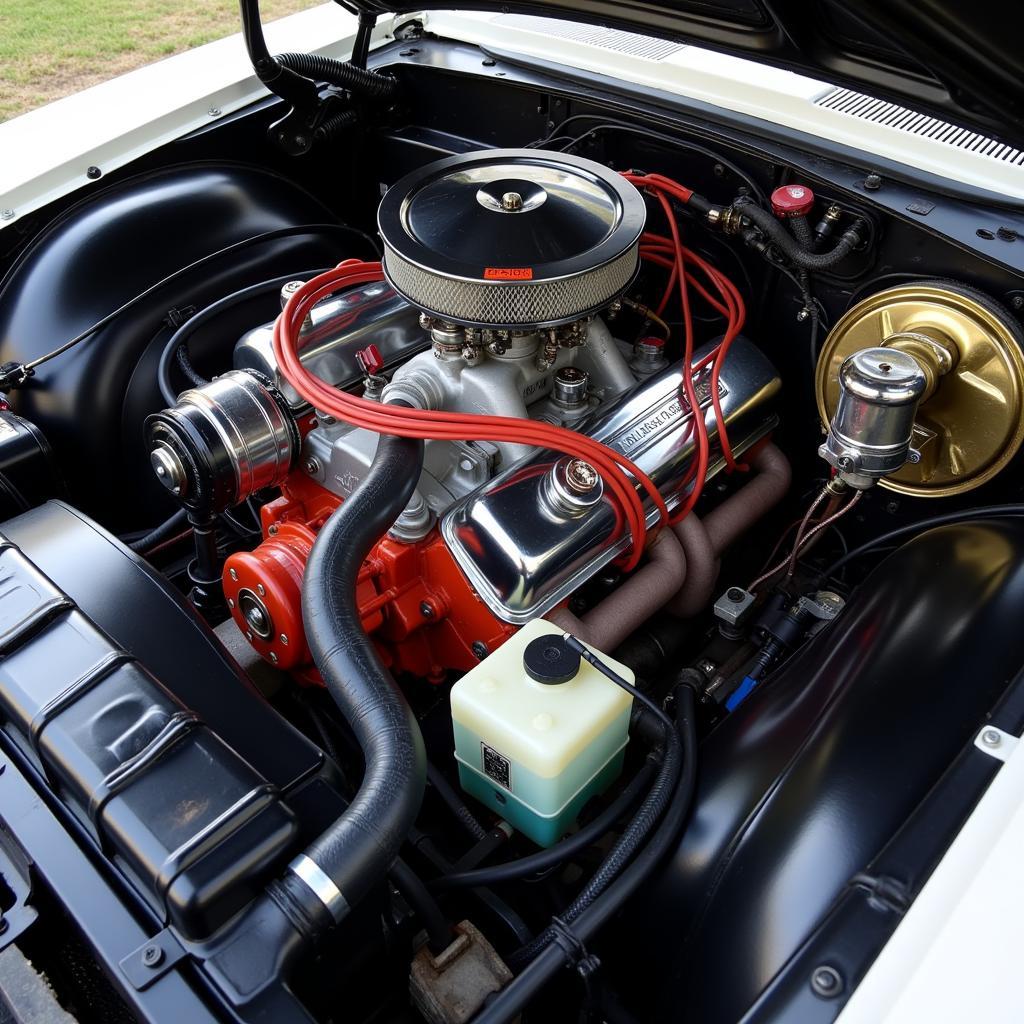

Engine with Fuel System Ol Drive

Engine with Fuel System Ol Drive

Jane Doe, another experienced mechanic, adds, “Regular maintenance is key. Just like any mechanical system, neglect can lead to significant problems down the line.”

Conclusion

Fuel system ol drive technology, though older, remains relevant for classic car enthusiasts. Understanding this system is vital for keeping these vehicles running smoothly and efficiently. By understanding the components, common problems, and maintenance requirements, you can ensure your classic car continues to perform at its best for years to come. Explore our page on npc jobs for more information. Consider a golf cart turbo kit for another project.

FAQ

- What is the main function of a fuel system ol drive? To mix air and fuel for combustion.

- What is the difference between open loop and closed loop fuel systems? Open loop doesn’t use sensor feedback.

- What are some common problems with fuel system ol drives? Clogged filters, faulty pumps, carburetor issues.

- How can I maintain a fuel system ol drive? Regular cleaning and part replacement.

- What are the advantages of a fuel system ol drive? Simplicity and ease of repair.

- What are the disadvantages of a fuel system ol drive? Lower fuel efficiency and higher emissions.

- Why is understanding my fuel system important? For better maintenance and troubleshooting.

When you need assistance, please contact us at Phone Number: 0915117113, Email: [email protected], or visit us at Address: To 3 Kp Binh An, Phu Thuong, Vietnam, Binh Phuoc 830000, Vietnam. We have a 24/7 customer service team.