J Hook Chains: A Comprehensive Guide

November 4, 2024J Hook Chains are versatile and essential tools used in a variety of applications, from lifting and rigging to securing cargo and even decorative purposes. Understanding their different types, proper usage, and safety precautions is crucial for ensuring both efficiency and safety. This guide will delve into everything you need to know about j hook chains, providing a detailed overview of their uses, advantages, and important considerations.

Understanding the Different Types of J Hook Chains

J hook chains are categorized based on material, size, and grade. The most common materials used are carbon steel, alloy steel, and stainless steel. Each material offers distinct properties, making them suitable for specific applications. For example, stainless steel j hook chains are ideal for corrosive environments, while alloy steel chains offer superior strength. Chain size is determined by the diameter of the link stock, and the grade signifies the chain’s working load limit. Understanding these distinctions is essential for choosing the right j hook chain for your specific needs.

Choosing the right chain involves considering factors like the weight of the load, the environment it will be used in, and the frequency of use. For lighter loads and general purposes, Grade 30 chain is often sufficient. However, for heavier loads and more demanding applications, Grade 80 or higher is recommended. It’s always better to err on the side of caution and choose a chain with a higher working load limit than necessary.

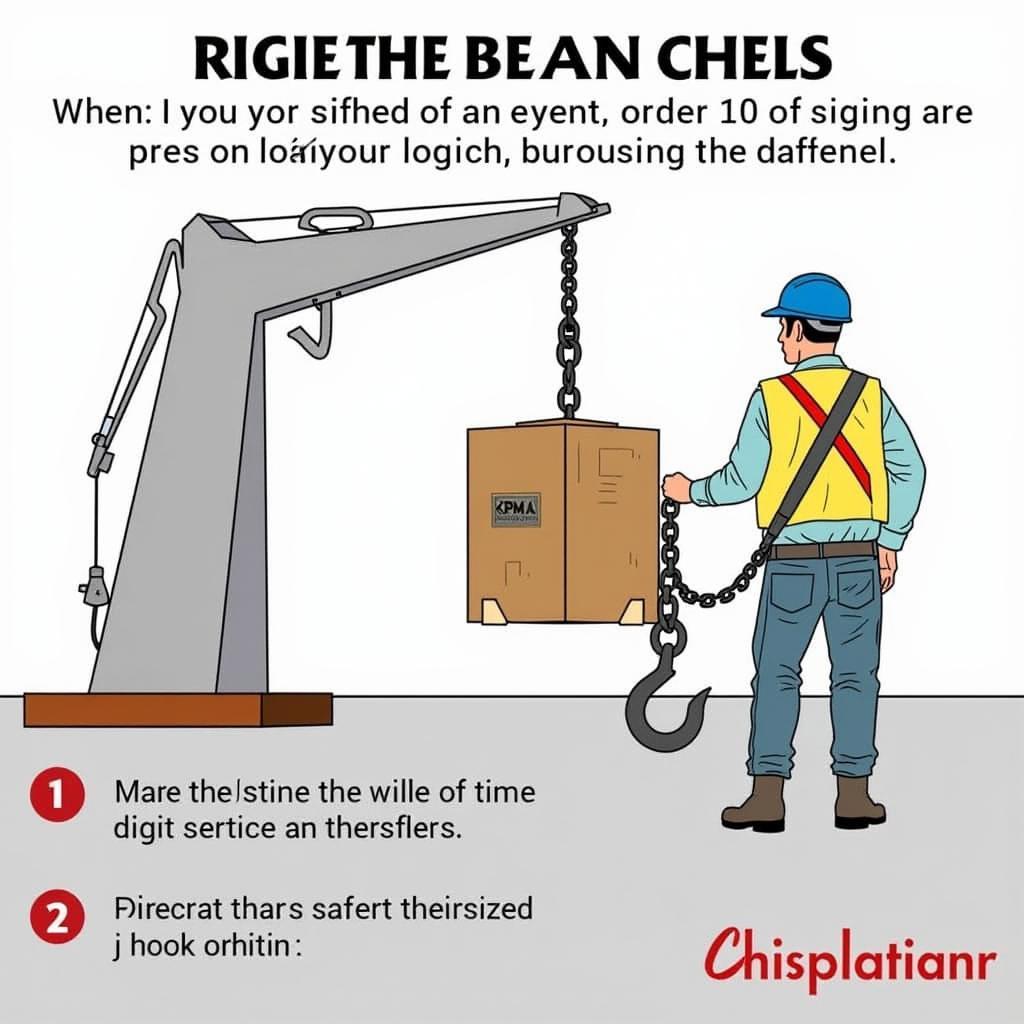

Safe Usage and Best Practices for J Hook Chains

Safety is paramount when working with j hook chains. Inspecting the chain for any signs of wear, damage, or deformation before each use is crucial. Never exceed the working load limit of the chain, and always use appropriate lifting equipment and techniques. Ensure the hook is properly seated and secured to prevent slippage. When storing j hook chains, keep them clean and dry to prevent rust and corrosion. Proper maintenance and storage will prolong the life of the chain and ensure its continued safe operation.

Proper rigging techniques are also crucial for safety. Avoid sharp bends or twisting of the chain, which can weaken its structure. Use appropriate slings and shackles to distribute the load evenly and prevent stress concentrations. Regular inspection of all components, including hooks, shackles, and slings, is essential to identify potential issues before they become hazards.

Safe Usage of J Hook Chains

Safe Usage of J Hook Chains

Advantages of Using J Hook Chains

J hook chains offer several advantages over other lifting and securing methods. Their robust construction provides excellent durability and strength, making them suitable for heavy-duty applications. The flexibility of the chain allows for easy maneuvering and adjustment, adapting to various load shapes and sizes. Unlike ropes or straps, j hook chains are resistant to abrasion and cutting, ensuring their longevity in harsh environments. The simple design of the j hook makes it easy to attach and detach, streamlining operations and saving time.

The versatility of j hook chains makes them indispensable in numerous industries. From construction and manufacturing to transportation and logistics, j hook chains provide a reliable and efficient solution for lifting, securing, and transporting various loads. Their adaptability and durability contribute to increased productivity and reduced downtime.

Conclusion

J hook chains are an invaluable tool for various lifting and securing needs. Understanding their different types, safe usage practices, and advantages is crucial for maximizing their effectiveness and ensuring safety. By choosing the correct chain for the application and following proper procedures, you can ensure the longevity of the chain and prevent accidents. Choosing the right j hook chain is an investment in safety and efficiency.

FAQ

- What is the working load limit of a j hook chain? The working load limit (WLL) is the maximum weight a chain can safely lift. It’s crucial to never exceed this limit.

- How do I inspect a j hook chain for damage? Look for signs of wear, cracks, stretching, or deformation in the links and the hook.

- What are the different grades of j hook chains? Common grades include 30, 43, 80, and 100, each with increasing strength.

- How do I store j hook chains properly? Store them in a clean, dry place to prevent rust and corrosion.

- What are the advantages of using alloy steel j hook chains? Alloy steel chains offer higher strength and durability compared to carbon steel.

- Can j hook chains be used in corrosive environments? Stainless steel j hook chains are recommended for corrosive environments.

- How do I choose the right size j hook chain? Consider the weight of the load and the application requirements.

Common Scenarios

- Securing cargo on a flatbed truck: Use appropriate grade and size chain with proper tie-down techniques.

- Lifting heavy machinery: Ensure the chain’s WLL exceeds the weight of the machinery and use proper rigging equipment.

- Towing a vehicle: Utilize a chain with sufficient strength and ensure secure attachment points.

Related Articles

- Chain Hoists and Their Applications

- Understanding Different Types of Hooks

- Safe Rigging Practices

If you need further assistance, please contact us at Phone Number: 0915117113, Email: [email protected] or visit us at: Tổ 3 Kp Bình An, Phú Thương, Việt Nam, Bình Phước 830000, Việt Nam. We have a 24/7 customer service team.