Understanding RPM Gearboxes: A Comprehensive Guide

October 14, 2024An Rpm Gearbox is a critical component in various mechanical systems, responsible for converting speed and torque to optimize performance. This guide delves into the intricacies of RPM gearboxes, exploring their functionality, applications, and benefits.

Types of RPM Gearboxes

Types of RPM Gearboxes

What is an RPM Gearbox?

An RPM gearbox, also known as a revolutions per minute gearbox, is a mechanical device that adjusts the speed and torque output of a motor to match the specific requirements of a driven load. It achieves this by utilizing a series of gears with varying ratios to manipulate the input speed and torque, resulting in a desired output.

How Does an RPM Gearbox Work?

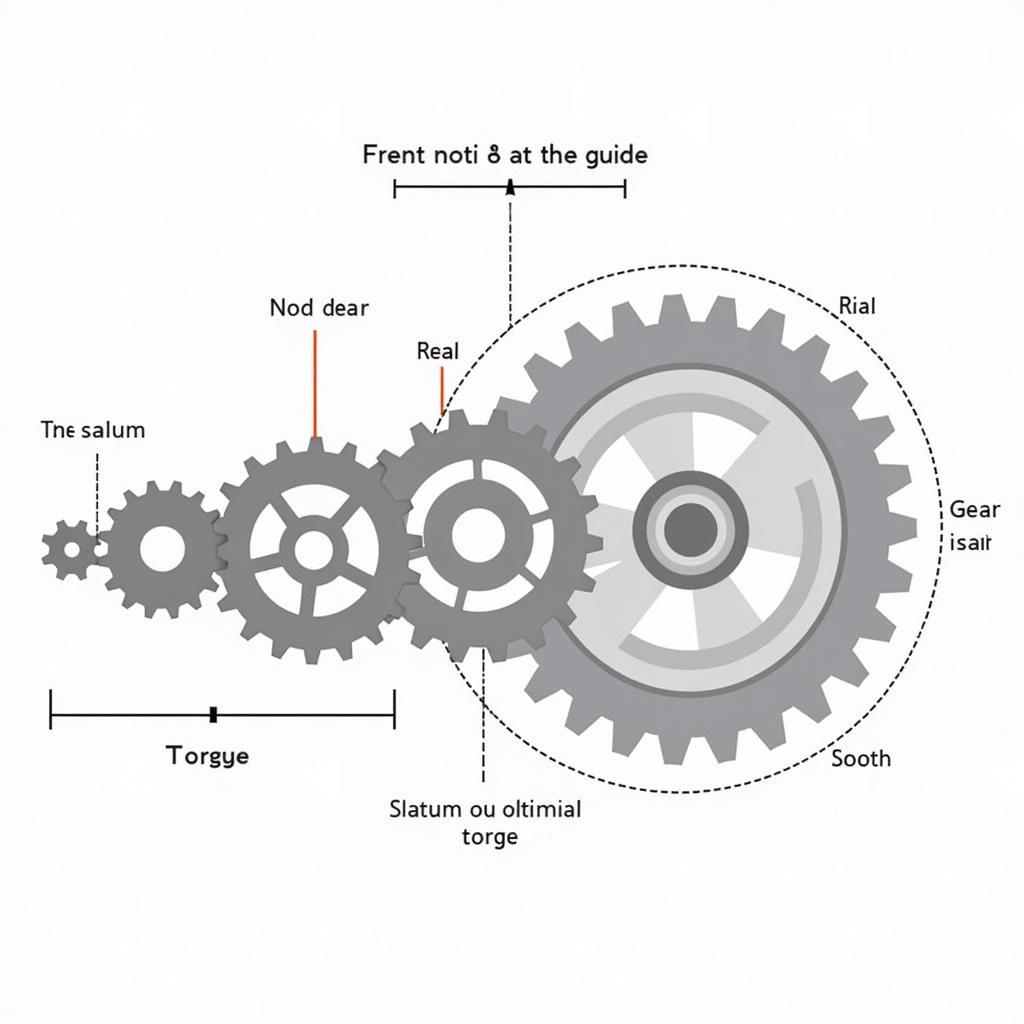

The fundamental principle behind an RPM gearbox lies in the interaction of gears with different numbers of teeth. When a small gear (driving gear) rotates a larger gear (driven gear), the speed of the driven gear decreases, while its torque increases proportionally. Conversely, if the larger gear drives the smaller gear, the speed increases, and the torque decreases. By combining multiple gear sets within a housing, RPM gearboxes can achieve a wide range of speed and torque conversions.

Types of RPM Gearboxes

Gear Reduction Mechanism

Gear Reduction Mechanism

There are various types of RPM gearboxes, each suited for specific applications:

- Spur Gearboxes: These gearboxes employ straight-toothed gears, making them cost-effective for simple applications with moderate speed and torque requirements.

- Helical Gearboxes: Utilizing helical gears with angled teeth, these gearboxes offer smoother and quieter operation, making them ideal for high-speed applications.

- Bevel Gearboxes: Designed for applications requiring a change in the direction of power transmission, typically 90 degrees, bevel gearboxes use conical gears for efficient power transfer.

- Worm Gearboxes: Characterized by a worm gear and a worm wheel, these gearboxes provide high gear ratios and self-locking capabilities, making them suitable for applications demanding precise control and high torque.

- Planetary Gearboxes: Known for their compact design and high torque-to-weight ratio, planetary gearboxes are often found in robotics and precision machinery.

Applications of RPM Gearboxes

Industrial Applications of RPM Gearboxes

Industrial Applications of RPM Gearboxes

RPM gearboxes find applications in a wide range of industries:

- Manufacturing: From conveyor belts to robotic arms, RPM gearboxes play a crucial role in automating production processes.

- Automotive: Transmissions in vehicles utilize RPM gearboxes to optimize engine power delivery to the wheels.

- Aerospace: Aircraft employ RPM gearboxes in various systems, including landing gear and flap actuators.

- Energy: Wind turbines utilize RPM gearboxes to convert the slow rotation of the blades into high-speed electricity generation.

- Robotics: Precise motion control in robots relies heavily on RPM gearboxes to achieve desired movements.

Benefits of Using RPM Gearboxes

- Increased Efficiency: By optimizing speed and torque, RPM gearboxes enhance the overall efficiency of mechanical systems.

- Improved Performance: Matching the output to the load requirements results in improved performance and reduced wear and tear.

- Compact Design: Many RPM gearboxes are designed to be compact, saving valuable space in various applications.

- Cost-Effectiveness: RPM gearboxes contribute to cost savings by reducing energy consumption and maintenance requirements.

Conclusion

RPM gearboxes are essential components in countless mechanical systems, enabling efficient power transmission and optimized performance. Understanding the different types, applications, and benefits of RPM gearboxes is crucial for selecting the right gearbox for specific needs. By carefully considering these factors, industries and individuals can leverage the power of RPM gearboxes to enhance efficiency, productivity, and overall system reliability.

FAQ

1. What factors should I consider when choosing an RPM gearbox?

2. How do I determine the correct gear ratio for my application?

3. What are the common maintenance requirements for RPM gearboxes?

4. What is the lifespan of a typical RPM gearbox?

5. Where can I find reliable suppliers of RPM gearboxes?

For any inquiries or assistance regarding RPM gearboxes, please contact us at Phone Number: 0915117113, Email: [email protected]. Our team of experts is available 24/7 to provide support. You can also visit us at our address: To 3 Kp Binh An, Phu Thuong, Viet Nam, Binh Phuoc 830000, Vietnam.