USA Made Tap and Die Set: A Comprehensive Guide

November 23, 2024Precision and durability are paramount when working with metal. A Usa Made Tap And Die Set offers just that, providing the tools you need for creating and repairing threads in a variety of materials. Whether you’re a professional machinist or a DIY enthusiast, understanding the nuances of these essential tools is key to achieving successful results.

Why Choose a USA Made Tap and Die Set?

American-made tools have long been synonymous with quality and craftsmanship. Investing in a USA made tap and die set means you’re getting tools built to last, crafted with precision and designed to withstand rigorous use. These sets often feature high-speed steel (HSS) or other premium materials, ensuring long-term performance and resistance to wear and tear. Furthermore, supporting American manufacturing contributes to the domestic economy and helps sustain skilled labor.

Durable USA Made Tap and Die Set

Durable USA Made Tap and Die Set

Benefits of Using a High-Quality Tap and Die Set

A quality tap and die set provides accurate and consistent threading, crucial for creating strong and reliable connections. It also reduces the risk of stripped threads or damaged workpieces. Whether you’re working on automotive repairs, plumbing projects, or general metal fabrication, a dependable tap and die set is indispensable.

Understanding Taps and Dies

Taps are used to create internal threads in a pre-drilled hole, while dies are used to cut external threads onto rods or bolts. A USA made tap and die set will typically include a range of sizes and thread pitches to accommodate various applications.

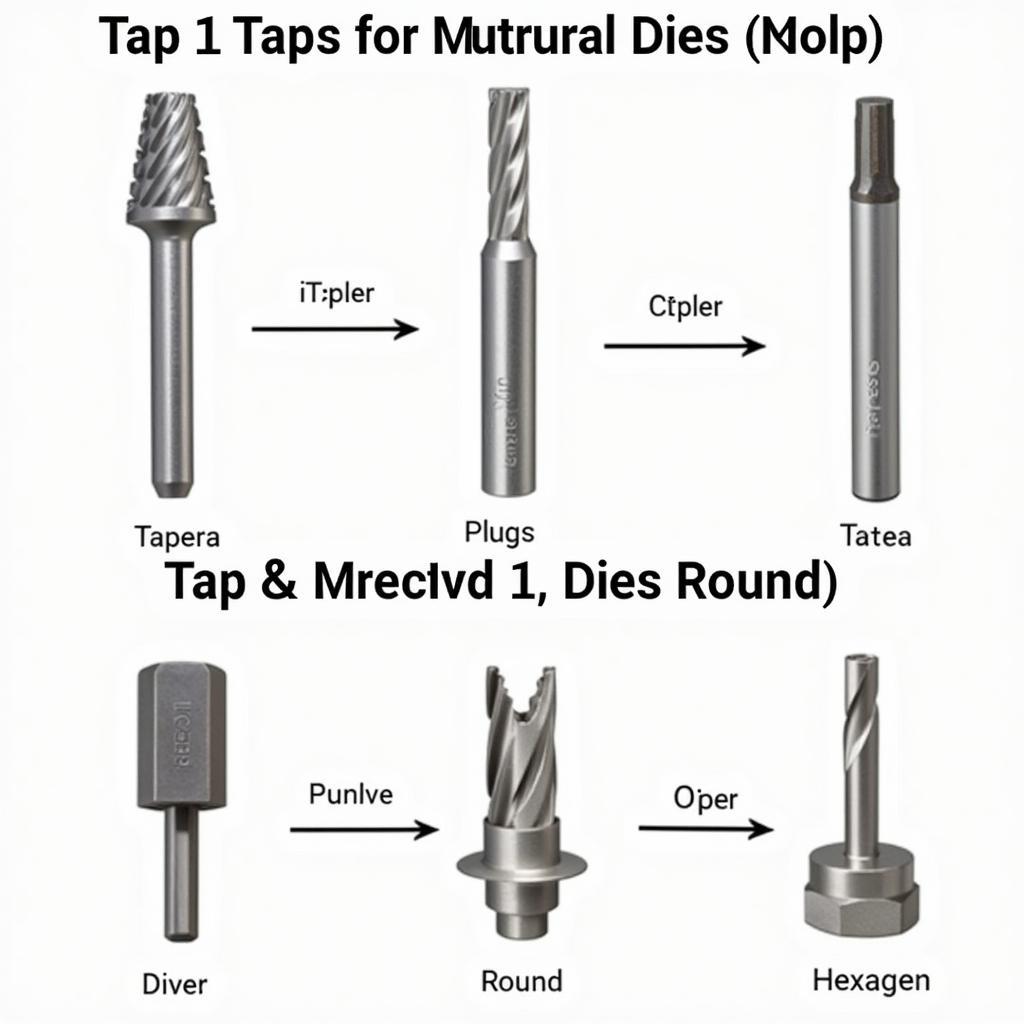

Types of Taps and Dies

- Taper Taps: Designed for starting threads and gradually cutting deeper.

- Plug Taps: Used for extending threads deeper into a hole.

- Bottoming Taps: Ideal for creating threads to the bottom of a blind hole.

- Round Dies: Commonly used for general threading purposes.

- Hexagon Dies: Offer better grip and control during threading.

Different Tap and Die Types for Various Threading Applications

Different Tap and Die Types for Various Threading Applications

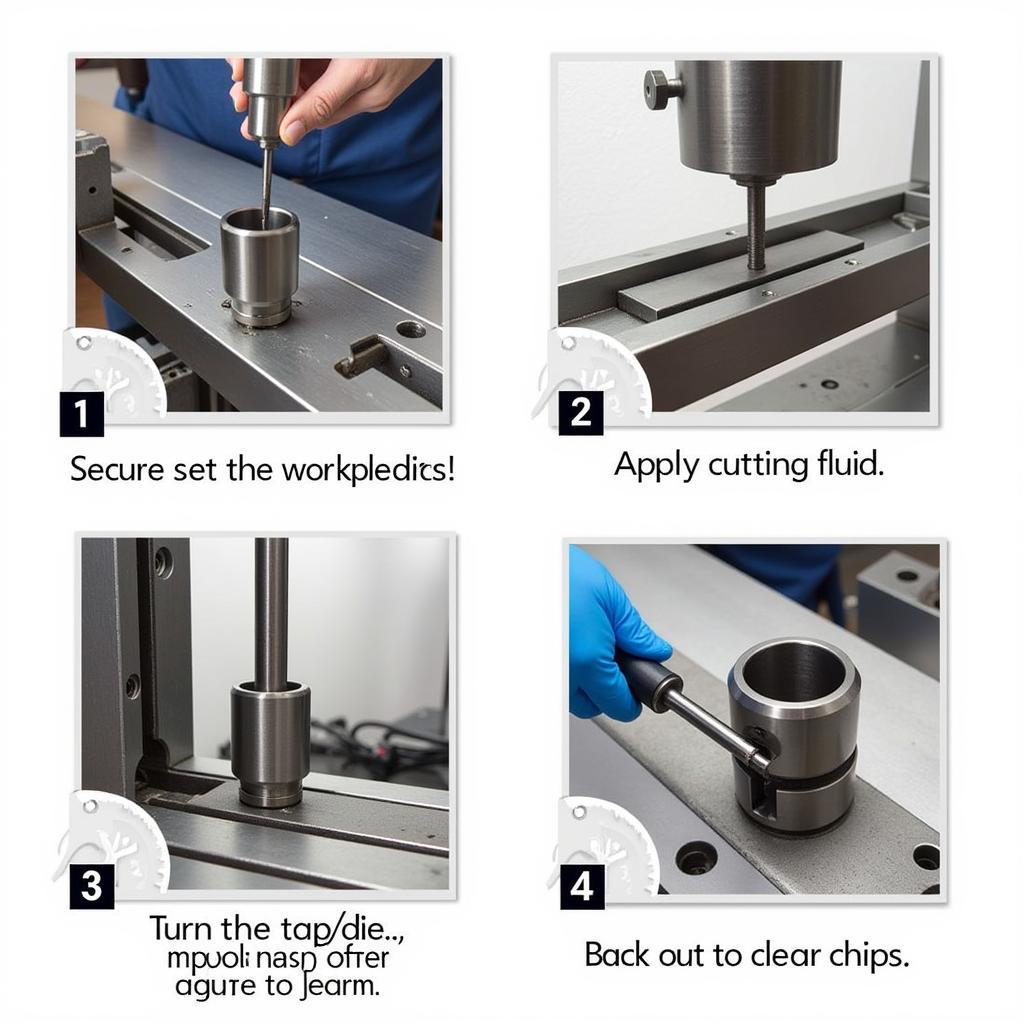

How to Use a Tap and Die Set

Using a tap and die set effectively requires proper technique and lubrication. Always ensure the workpiece is securely clamped and use a suitable cutting fluid to reduce friction and heat buildup.

Step-by-Step Guide to Tapping

- Drill a pilot hole: The correct size is crucial for optimal thread engagement.

- Secure the tap: Use a tap wrench for proper alignment and control.

- Apply cutting fluid: Lubrication is key to smooth and accurate tapping.

- Tap the hole: Turn the tap clockwise, applying even pressure.

- Back out the tap: Periodically reverse the tap to clear chips.

Step-by-Step Guide to Dieing

- Chamfer the end of the rod: This ensures smooth thread starting.

- Secure the die: Use a die stock for proper alignment and grip.

- Apply cutting fluid: Lubrication is essential for smooth threading.

- Turn the die: Rotate the die clockwise onto the rod.

- Back out the die: Periodically reverse the die to clear chips.

Proper Technique for Using a Tap and Die Set

Proper Technique for Using a Tap and Die Set

Maintaining Your Tap and Die Set

Proper storage and cleaning are essential for maintaining the longevity of your USA made tap and die set. Keep the tools in a dry, protected environment and clean them after each use to remove metal shavings and cutting fluid residue.

Expert Insight from John Miller, Master Machinist: “Investing in a quality tap and die set is a wise decision for any serious metalworker. Proper maintenance will ensure these tools serve you faithfully for years to come.”

In conclusion, a USA made tap and die set is a valuable investment for anyone working with metal. Choosing high-quality tools, understanding their proper use, and maintaining them diligently will guarantee precise and durable threading results for all your projects. Consider a USA-made set for your next project!

FAQs

- What is the best material for a tap and die set? High-speed steel (HSS) is a popular choice for its durability and resistance to wear.

- How do I choose the right tap and die size? Consult a tap and die chart to determine the correct size based on the desired thread size and pitch.

- What type of cutting fluid should I use? A general-purpose cutting oil is suitable for most tapping and dieing operations.

- How do I prevent stripped threads? Use the correct tap and die size, apply sufficient cutting fluid, and avoid excessive force.

- How do I store my tap and die set? Store the tools in a dry, protected environment, preferably in a dedicated tool box or organizer.

Expert Insight from Sarah Johnson, Mechanical Engineer: “Accurate threading is crucial for creating strong and reliable connections. A quality tap and die set is essential for achieving this precision.”

Need assistance? Contact us at Phone Number: 0915117113, Email: [email protected] Or visit us at: To 3 Kp Binh An, Phu Thuong, Vietnam, Binh Phuoc 830000, Vietnam. We have a 24/7 customer service team.